Short Lead Time for Graphite Electrode For Ladle Furnace - Ultra High Power Graphite Electrode – Hexi

Short Lead Time for Graphite Electrode For Ladle Furnace - Ultra High Power Graphite Electrode – Hexi Detail:

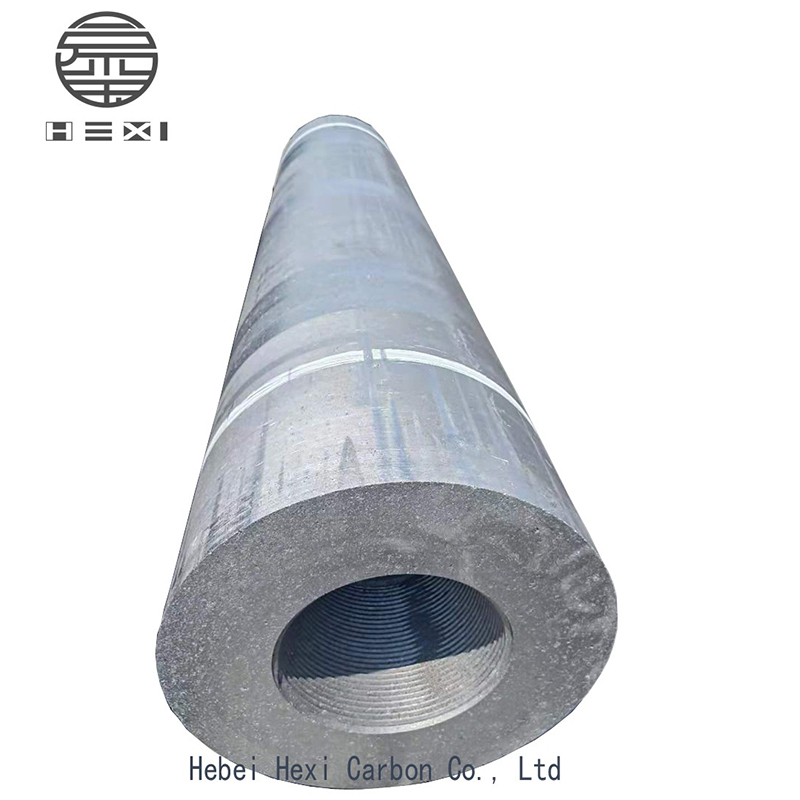

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking.

The standard of ultra-high power graphite electrode and nipple

UHP Graphite electrode Permissible current load

Ultra-high-power graphite electrode produced by Hexin Carbon is produced by high-grade needle coke, and its graphitization heat treatment is carried out in an internal series graphitization furnace, and the graphitization temperature is as high as 2800〜3000°C, so the resistivity is lower, allowing a larger current density, a smaller linear expansion coefficient and excellent thermal shock resistance. It is a special ultra-high power graphite electrode for electric arc furnace and ladle refining furnace. The ultra-high power graphite electrode of Hexi Carbon Company adopts the most advanced technology and is produced in strict accordance with the global standards, which basically meets the world-class quality standards. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Product detail pictures:

Related Product Guide:

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Short Lead Time for Graphite Electrode For Ladle Furnace - Ultra High Power Graphite Electrode – Hexi, The product will supply to all over the world, such as: Mecca, Adelaide, Myanmar, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.