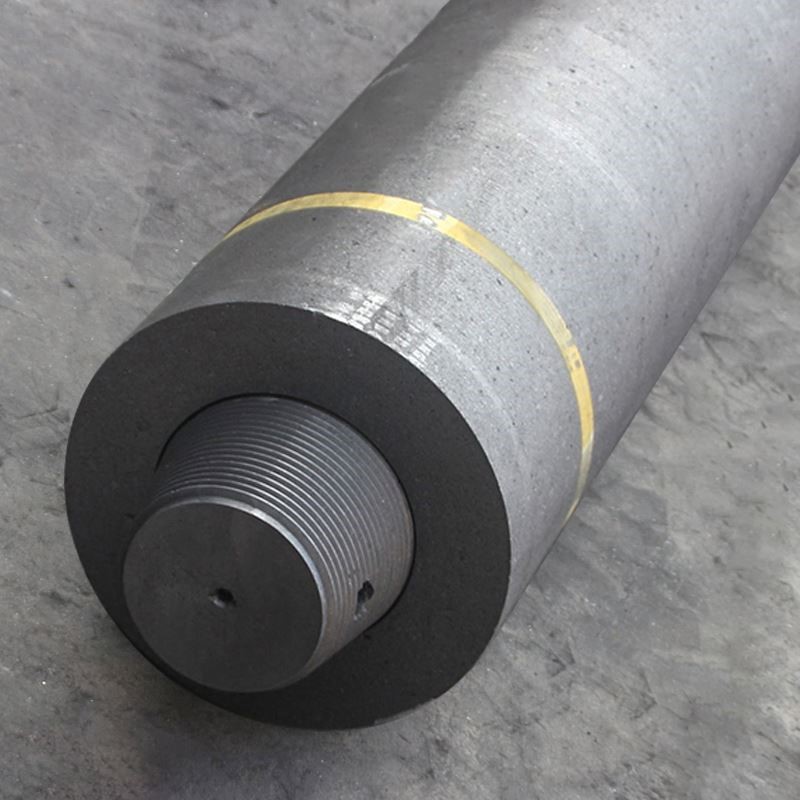

RP 400 Ordinary power graphite electrode

RP 400mm Graphite Electrode

For materials with the same average particle size, the strength and hardness of materials with low resistivity are also slightly lower than those with high resistivity.

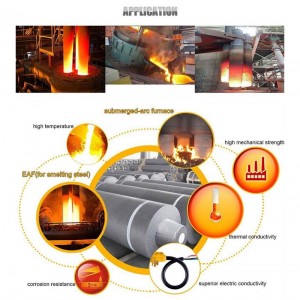

For materials with the same average particle size, the strength and hardness of materials with low resistivity are also slightly lower than those with high resistivity. That is, discharge rate, loss will vary. Therefore, the natural resistivity of graphite electrode materials, in practical applications need to choose the material is very important. The selection of electrode material is directly related to the effect of discharge. To a large extent, the selection of material is appropriate, which determines the discharge speed, machining accuracy and surface roughness. Due to the different quality requirements of ordinary power, high power and ultra-high power graphite electrode, the aggregate composition of the preparation is also different. From the perspective of industry product trends, the development of graphite electrode to ultra-high power electrode is the future trend. The joints can be made with 3 or 4 buttons and are manufactured strictly within the industry standard tolerance range. Long and short specifications can be customized according to customer requirements, short processing time, strong production capacity, to meet the needs of customers at home and abroad.

|

Typical Properties |

|||

|

Properties |

Position |

Unit |

RP |

|

300-800mm |

|||

|

Specific Rresistance |

body |

μΩm |

7.8-8.8 |

|

nipple |

5.0-6.5 |

||

|

Bendin Strengh |

body |

mpa |

7.0-12.0 |

|

nipple |

15.0-20.0 |

||

|

Young's Modulus |

body |

cpa |

7.0-9.3 |

|

nipple |

12.0-14.0 |

||

|

Bulk Density |

body |

g/cm³ |

1.60-1.65 |

|

nipple |

1.70-1.74 |

||

|

CTE(100-600℃) |

body |

×10-6/℃ |

2.2-2.6 |

|

nipple |

2.0-2.5 |

||

|

Ash Content |

% |

0.5 |

|