Reasonable price High Density Graphite Electrodes - UHP 550mm Graphite Electrode – Hexi

Reasonable price High Density Graphite Electrodes - UHP 550mm Graphite Electrode – Hexi Detail:

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure.

What’s the funtion of graphitization?

*Improve the electrical and thermal conductivity

*Improve the thermal shock resistance and chemical stability (the linear expansion coefficient is reduced by 50-80%);

*Make the carbon material have lubricity and wear resistance;

*Discharge impurities and improve the purity of the carbon material (the ash content of the product is reduced from 0.5% to about 0.3%).

| Comparison Technical Specification for UHP Graphite Electrode 22″ | ||

| Electrode | ||

| Item | Unit | Supplier Spec |

| Typical Characteristics of Pole | ||

| Nominal Diameter | mm | 550 |

| Max Diameter | mm | 562 |

| Min Diameter | mm | 556 |

| Nominal Length | mm | 1800-2400 |

| Max Length | mm | 1900-2500 |

| Min Length | mm | 1700-2300 |

| Bulk Density | g/cm3 | 1.68-1.72 |

| transverse strength | MPa | ≥12.0 |

| Young’ Modulus | GPa | ≤13.0 |

| Specific Resistance | µΩm | 4.5-5.6 |

| Maximum current density | KA/cm2 | 18-27 |

| Current Carrying Capacity | A | 45000-65000 |

| (C.T.E) | 10-6℃ | ≤1.2 |

| ash content | % | ≤0.2 |

| Typical Characteristics of Nipple (4TPI) | ||

| Bulk Density | g/cm3 | 1.78-1.84 |

| transverse strength | MPa | ≥22.0 |

| Young’ Modulus | GPa | ≤18.0 |

| Specific Resistance | µΩm | 3.4~3.8 |

| (C.T.E) | 10-6℃ | ≤1.0 |

| ash content | % | ≤0.2 |

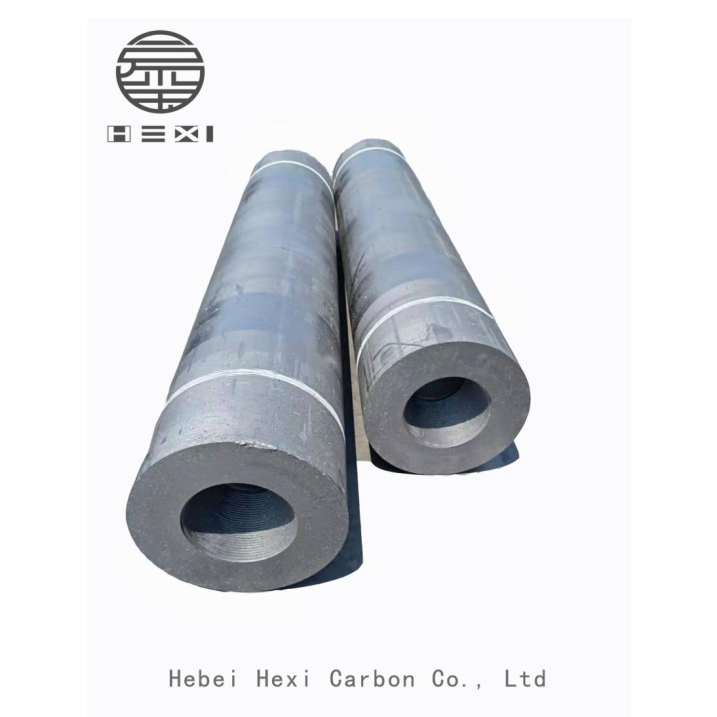

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Reasonable price High Density Graphite Electrodes - UHP 550mm Graphite Electrode – Hexi, The product will supply to all over the world, such as: Singapore, Netherlands, Sao Paulo, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.