Professional China High Power Carbon Graphite Electrodes - Ultra High Power Graphite Electrode – Hexi

Professional China High Power Carbon Graphite Electrodes - Ultra High Power Graphite Electrode – Hexi Detail:

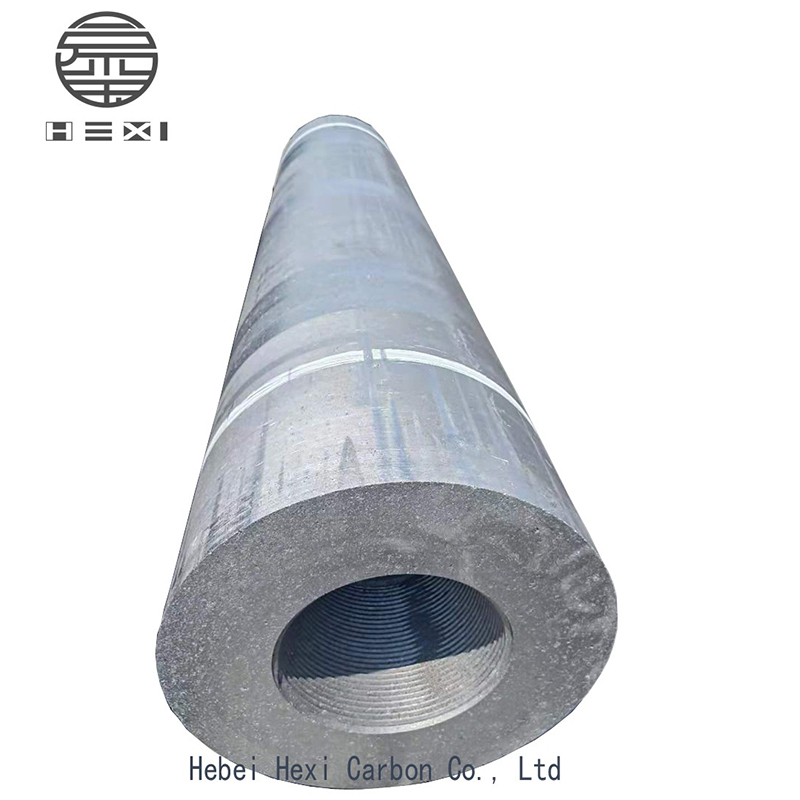

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking.

The standard of ultra-high power graphite electrode and nipple

UHP Graphite electrode Permissible current load

Ultra-high-power graphite electrode produced by Hexin Carbon is produced by high-grade needle coke, and its graphitization heat treatment is carried out in an internal series graphitization furnace, and the graphitization temperature is as high as 2800〜3000°C, so the resistivity is lower, allowing a larger current density, a smaller linear expansion coefficient and excellent thermal shock resistance. It is a special ultra-high power graphite electrode for electric arc furnace and ladle refining furnace. The ultra-high power graphite electrode of Hexi Carbon Company adopts the most advanced technology and is produced in strict accordance with the global standards, which basically meets the world-class quality standards. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Product detail pictures:

Related Product Guide:

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for Professional China High Power Carbon Graphite Electrodes - Ultra High Power Graphite Electrode – Hexi, The product will supply to all over the world, such as: Latvia, Myanmar, Provence, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!