PriceList for High-Purity Graphite Electrode - 400 UHP graphite electrode – Hexi

PriceList for High-Purity Graphite Electrode - 400 UHP graphite electrode – Hexi Detail:

Graphite electrodes are mainly used in the steelmaking process. Iron scrap gets melted in an electric arc furnace and recycled. As a kind of conductor, they are an essential component in this kind of

UHP graphite electrode is mainly made up of high-quality needle coke,and widely used in ultra high power electric arc furnaces.It is capable of carrying the current density more than 25A/cm2

| Standard for ultra high power graphite electrodes and connectors | |||||

|

items |

unit |

nominal diameter(mm) |

|||

|

250~400 |

450~550 |

600~700 |

|||

|

specific resistance |

electrode nipple |

μ Ω•m |

4.8~5.8 3.4~4.0 |

4.5~5.6 3.4~3.8 |

4.5~5.4 3.0~3.6 |

|

transverse strength |

electrode nipple |

MPa |

≥12.0 ≥22.0 |

≥12.0 ≥22.0 |

≥10.0 ≥24.0 |

|

elastic modulus |

electrode nipple |

GPa |

≤13.0 ≤18.0 |

≤13.0 ≤18.0 |

≤13.0 ≤20.0 |

|

ash content |

electrode nipple |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

bulk density |

electrode nipple |

g/m³ |

1.68~1.73 1.78~1.84 |

1.68~1.72 1.78~1.84 |

1.68~1.72 1.80~1.86 |

|

C.T.E) |

electrode nipple |

10℃ |

≤1.2 ≤1.0 |

≤1.2 ≤1.0 |

≤1.2 ≤1.0 |

Manufacturing process

Graphite electrode is mainly made of petroleum coke and needle coke, mixed with coal pitch, getting through processes of calcinations, kneading, forming, baking, graphitizing and machining, finally to be products. Here are some explanations for some production process:

Kneading: Stirring and mixing a certain amount of carbon particles and powder with a certain amount of binder at a certain temperature, this process is called kneading.

The function of kneading

①Mix all kinds of raw materials evenly, and at the same time make solid carbon materials of different particle sizes uniformly mix and fill, and improve the density of the mixture;

②After adding coal asphalt, get all material firmly together.

③Some coal pitches penetrate into the internal voids, which further improves the density and adhesion of the paste.

Forming: The kneaded carbon paste is extruded into a green body (or green product) with a certain shape, size, density and strength in a molding equipment. The paste has a plastic deformation under the external force.

Roasting also called baking, It is a high temperature treatment, making the coal pitch carbonized to coke formed, which consolidate the carbonaceous aggregates and powder particles together with high mechanical strength, lower resistivity, better thermal stability and chemical stability.

Secondary roasting is to bake one more time, making the penetrating pitch carbonized . Electrodes (all types except RP) and nipples that require higher bulk density are required to be second-baked, and nipples three-dip four-bake or two-dip three-bake.

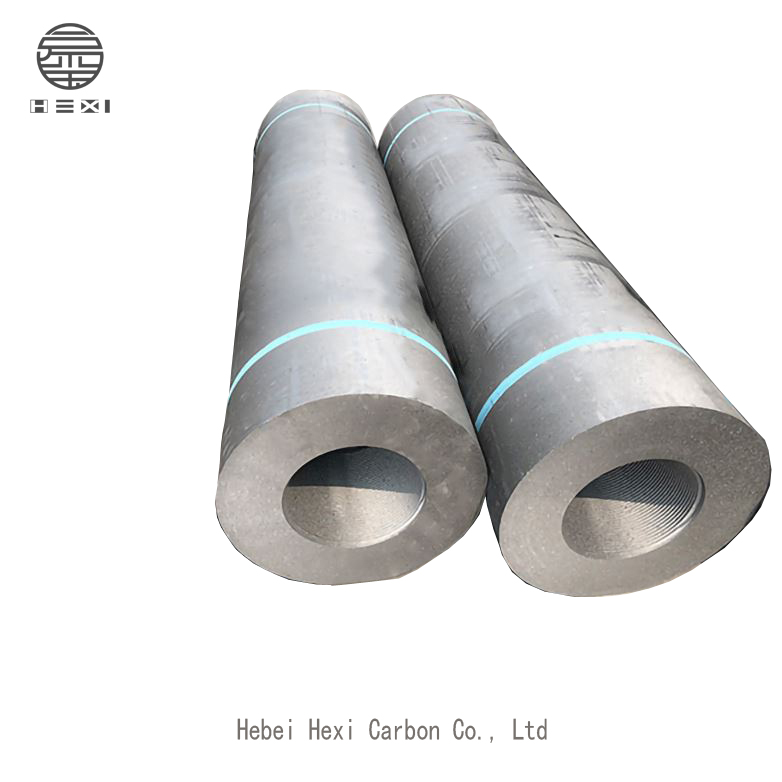

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for PriceList for High-Purity Graphite Electrode - 400 UHP graphite electrode – Hexi, The product will supply to all over the world, such as: Muscat, Belize, Sacramento, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,