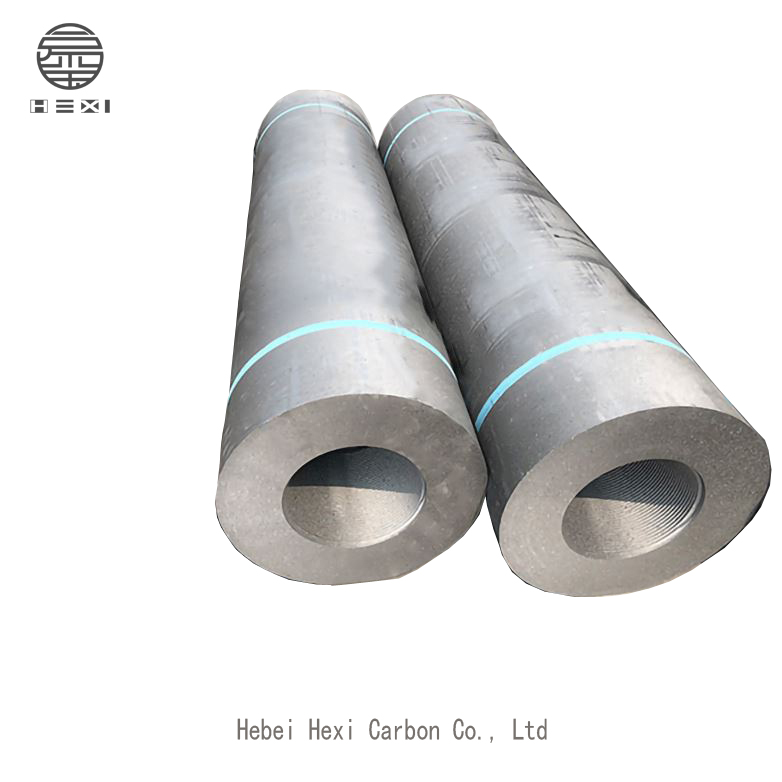

OEM Manufacturer Graphite Electrodes For Arc Furnaces - 400mm high power graphite electrode – Hexi

OEM Manufacturer Graphite Electrodes For Arc Furnaces - 400mm high power graphite electrode – Hexi Detail:

HP 400mm graphite electrode is mainly made of petroleum coke and needle coke. The allowable current is 21000-31000A, and the current density can be 16-24A/cm². Generally used for high-power electric arc furnace steelmaking.

The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing.

|

高功率石墨电极和接头标准 High power graphite electrode and joint standard |

|||||

|

项目items |

单位unit |

公称直径 nominal diameter(mm) |

|||

|

200~400 |

450~550 |

550~700 |

|||

|

电阻率 specific resistance |

电极接头 electrode nipple |

μ Ω•m |

5.2~6.5 3.5~4.5 |

5.2~6.5 3.5~4.5 |

5.2~6.5 3.2~4.3 |

|

抗折强度 transverse strength |

电极接头 electrode nipple |

MPa |

≥11.0 ≥22.0 |

≥11.0 ≥22.0 |

≥10.0 ≥22.0 |

|

弹性模量 elastic modulus |

电极接头 electrode nipple |

GPa |

≤12.0 ≤15.0 |

≤12.0 ≤15.0 |

≤12.0 ≤15.0 |

|

灰分 ash content |

电极接头 electrode nipple |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

体积密度 bulk density |

电极接头 electrode nipple |

g/m³ |

1.68~1.73 1.78~1.83 |

1.68~1.73 1.78~1.83 |

1.68~1.72 1.78~1.83 |

|

热膨胀系数 (C.T.E) |

电极接头 electrode nipple |

10℃ |

≤2.0 ≤1.8 |

≤2.0 ≤1.8 |

≤2.0 ≤1.8 |

Hexi Carbon is a manufacturing company that produces, sells, exports and provides a wide range of high-power graphite electrodes. The high-power graphite electrodes produced by our company have models with diameters from 350mm to 700mm for you to choose, and other graphite electrode models you need can also be customized.

|

高功率石墨电极允许的电流负载 Allowable current load for high-power graphite electrodes |

|||||

|

公称直径 nominal diameter |

允许电流 allowable current |

公称直径 nominal diameter |

允许电流 allowable current |

||

|

mm |

A |

A/㎡ |

mm |

A |

A/㎡ |

|

200 |

6500~10000 |

18~25 |

450 |

25000~40000 |

15~24 |

|

250 |

8000~13000 |

17~27 |

500 |

30000~48000 |

15~24 |

|

300 |

13000~17500 |

17~24 |

550 |

34000~53000 |

14~22 |

|

350 |

17400~24000 |

17~24 |

600 |

38000~58000 |

13~21 |

|

400 |

21000~31000 |

16~24 |

700 |

45000~72000 |

12~19 |

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for OEM Manufacturer Graphite Electrodes For Arc Furnaces - 400mm high power graphite electrode – Hexi, The product will supply to all over the world, such as: Sydney, Bahrain, Brisbane, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.