OEM Factory for Graphite Electrode For Arc Furnaces - Ultra High Power Graphite Electrode – Hexi

OEM Factory for Graphite Electrode For Arc Furnaces - Ultra High Power Graphite Electrode – Hexi Detail:

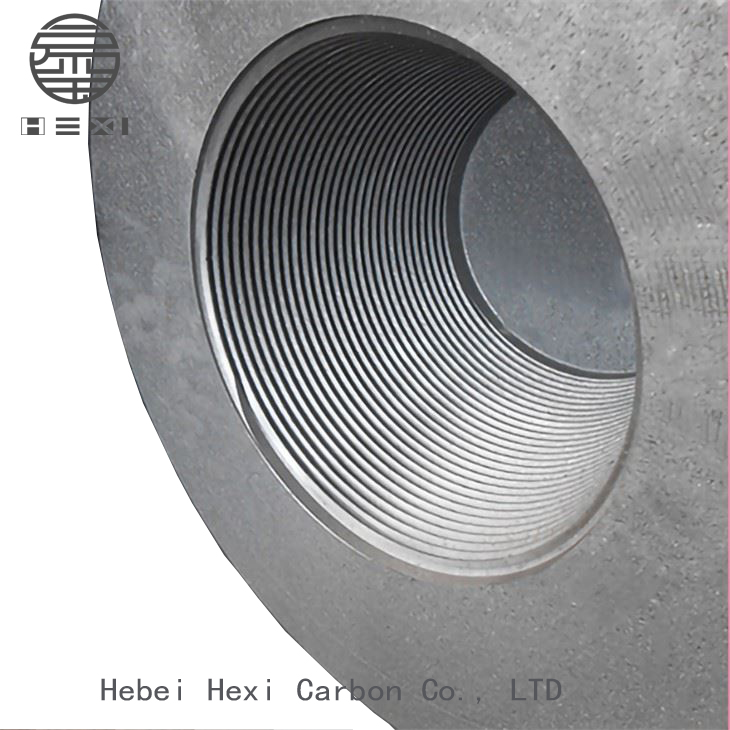

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking.

Used In Arc Steel-Making Furnace

the graphite electrode material used for electric arc steelmaking furnace is mainly used for electric furnace steelmaking. Electric Furnace steelmaking is to use the study of graphite electrode into the furnace working current, a strong current at the bottom of the electrode through these gas environment can produce influence arc discharge, the use of arc heat to smelting. The size of the capacitance, with graphite electrodes having electrodes of different diameters that can be used continuously, against the connection between the electrodes of the electrode joint. About 70 ~ 80% of the total amount of graphite electrode used in China is graphite used as electrode material for steelmaking.

The standard of ultra-high power graphite electrode and nipple

UHP Graphite electrode Permissible current load

Ultra-high-power graphite electrode produced by Hexin Carbon is produced by high-grade needle coke, and its graphitization heat treatment is carried out in an internal series graphitization furnace, and the graphitization temperature is as high as 2800〜3000°C, so the resistivity is lower, allowing a larger current density, a smaller linear expansion coefficient and excellent thermal shock resistance. It is a special ultra-high power graphite electrode for electric arc furnace and ladle refining furnace. The ultra-high power graphite electrode of Hexi Carbon Company adopts the most advanced technology and is produced in strict accordance with the global standards, which basically meets the world-class quality standards. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Transport of electrodes

The electrode must be covered with rain proof shed cloth during transportation.

Product detail pictures:

Related Product Guide:

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for OEM Factory for Graphite Electrode For Arc Furnaces - Ultra High Power Graphite Electrode – Hexi, The product will supply to all over the world, such as: Netherlands, French, Mexico, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!