Manufacturing Companies for Small Size Graphite Electrode - RP 350 Ordinary power graphite electrode – Hexi

Manufacturing Companies for Small Size Graphite Electrode - RP 350 Ordinary power graphite electrode – Hexi Detail:

|

普通功率石墨电极和接头标准 Common power graphite electrode joints and joint standards |

||||||

|

项目items |

单位unit |

公称直径 nominal diameter(mm) |

||||

|

100~200 |

250~300 |

350~600 |

780~1400 |

|||

|

电阻率 specific resistance |

电极接头 electrode nipple |

μ Ω•m |

7.5~8.5 5.8~6.5 |

7.5~8.5 5.8~6.5 |

7.5~8.5 5.8~6.5 |

8.5~10.5 5.8~6.5 |

|

抗折强度 transverse strength |

电极接头 electrode nipple |

MPa |

≥10.0 ≥16.0 |

≥9.0 ≥16.0 |

≥8.5 ≥16.0 |

≥7.0 ≥16.0 |

|

弹性模量 elastic modulus |

电极接头 electrode nipple |

GPa |

≤9.3 ≤13.0 |

≤9.3 ≤13.0 |

≤9.3 ≤13.0 |

≤12.0 ≤13.0 |

|

灰分 ash content |

电极接头 electrode nipple |

% |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.3 |

|

体积密度 bulk density |

电极接头 electrode nipple |

g/m³ |

1.55~1.64 ≥1.74 |

1.55~1.64 ≥1.74 |

1.55~1.63 ≥1.74 |

1.55~1.63 ≥1.74 |

|

热膨胀系数 (C.T.E) |

电极接头 electrode nipple |

10℃ |

≤2.4 ≤2.0 |

≤2.4 ≤2.0 |

≤2.4 ≤2.0 |

≤2.4 ≤2.0 |

|

普通功率石墨电极允许的电流负载 Current load allowed by ordinary power graphite electrodes |

|||||

|

公称直径 nominal diameter |

允许电流 allowable current |

公称直径 nominal diameter |

允许电流 allowable current |

||

|

mm |

A |

A/㎡ |

mm |

A |

A/㎡ |

|

100 |

1500~2400 |

19~30 |

400 |

18000~23500 |

14~18 |

|

150 |

3000~4500 |

16~25 |

450 |

22000~27000 |

13~17 |

|

200 |

5000~7000 |

15~21 |

500 |

25000~32000 |

13~16 |

|

250 |

7000~10000 |

14~20 |

550 |

28000~3458000 |

12~14 |

|

300 |

10000~13000 |

14~18 |

600 |

30000~36000 |

11~13 |

|

350 |

13500~18000 |

14~18 |

780~1400 |

57000~108000 |

12~8 |

Graphitization refers to the high temperature heat treatment process of transforming amorphous carbon into three-dimensional ordered planar hexagonal mesh laminated graphite by heating carbon products to 2300℃ or above in a high temperature electric furnace. The graphitization of carbon materials is carried out at a high temperature of 2300 ~ 3000℃. Because the combustion of fossil fuels is difficult to obtain such a high temperature, it can only be achieved by electric heating roasting in industry.

The products of Hexi have passed ISO9001 quality management system certification and obtained the export qualification of graphite electrode authorized by Chinese government. With good quality and excellent after-sales service, our products are in great demand in the world market.

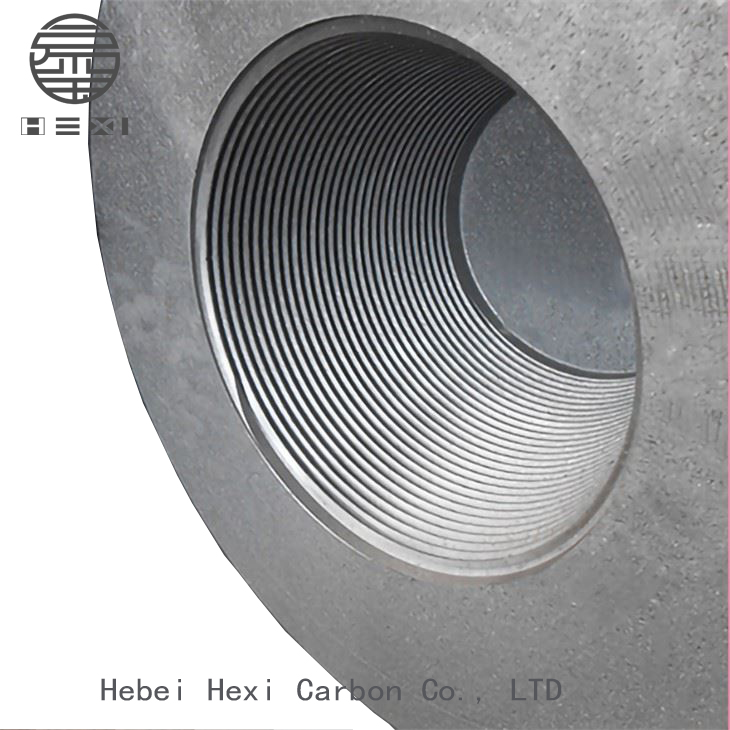

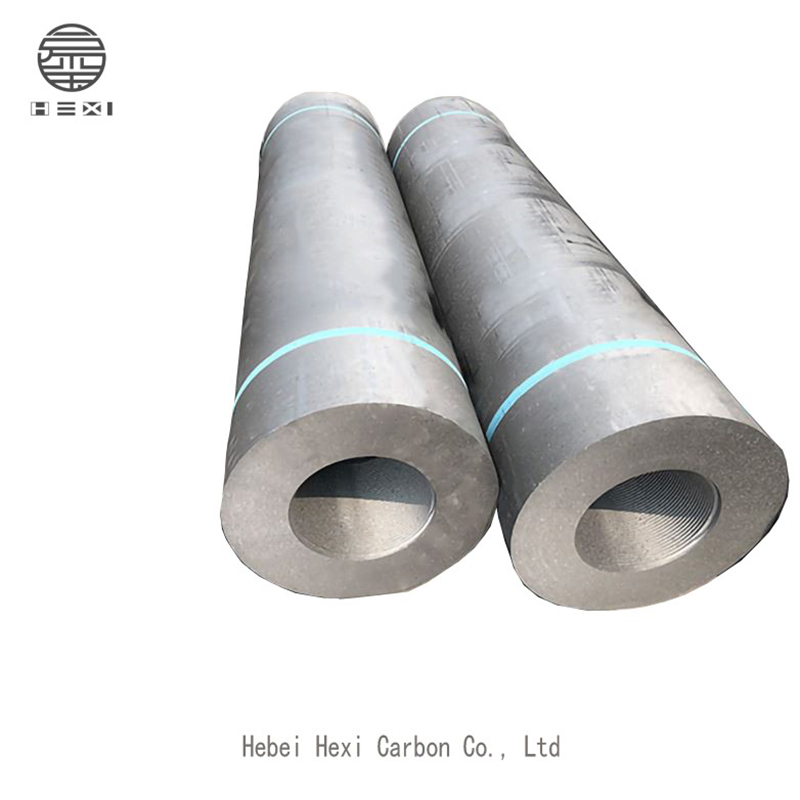

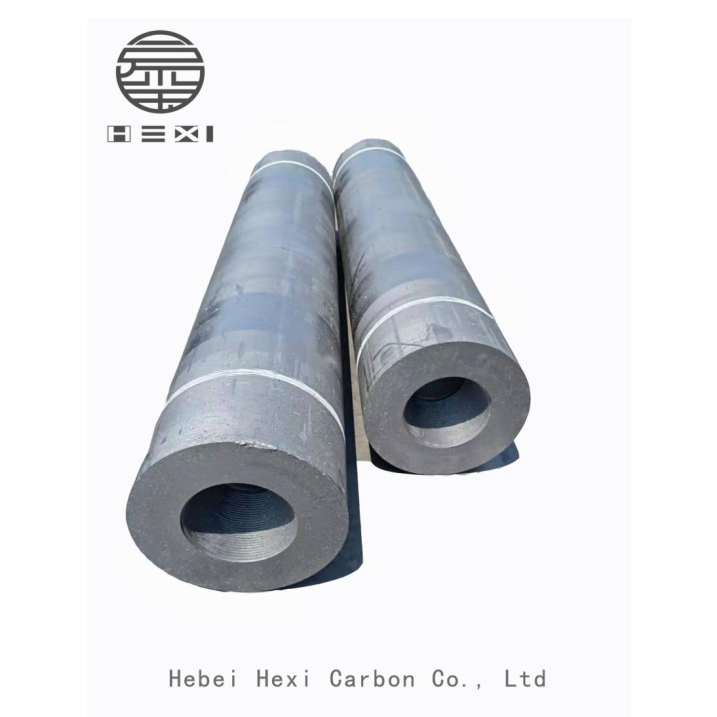

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Manufacturing Companies for Small Size Graphite Electrode - RP 350 Ordinary power graphite electrode – Hexi, The product will supply to all over the world, such as: Colombia, Venezuela, Brasilia, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.