Manufacturing Companies for Graphite Electrodes For Arc Furnace - High Power Graphite electrode – Hexi

Manufacturing Companies for Graphite Electrodes For Arc Furnace - High Power Graphite electrode – Hexi Detail:

High-power graphite electrodes are produced from high-quality petroleum coke (or low-grade needle coke). The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing. The raw material of nipple is imported oil needle coke, and the production process includes twice dipping and three baking. Its physical and mechanical properties are higher than those of ordinary power graphite electrodes, such as lower resistivity and higher current density.

Used In Mine Electric Furnace

used in electric furnaces for the production of iron alloys, pure silicon, yellow phosphorus, calcium carbide and matte, characterized by the fact that the lower part of the conducting electrode is buried in the charge, so that in addition to the heat generated by the electric arc between the plate and the charge, heat is also produced by the resistance of the charge as the current passes through it.

The standard of high power graphite electrode and nipple

HP Graphite electrode Permissible current load

Hexi Carbon is a manufacturing company that produces, sells, exports and provides high-power graphite electrodes for wide application. Our company has been advocating the use of better materials and more advanced production technology to reduce the energy consumption and material cost of products. The high-power graphite electrode produced by our company has the characteristics of high density, low power consumption and high conductivity. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

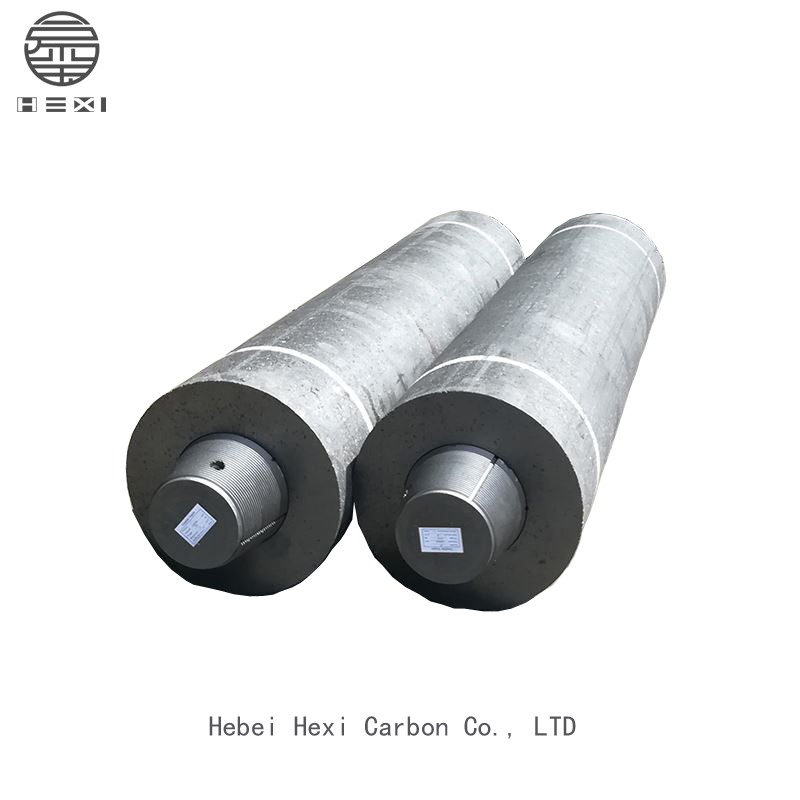

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Manufacturing Companies for Graphite Electrodes For Arc Furnace - High Power Graphite electrode – Hexi, The product will supply to all over the world, such as: South Africa, Afghanistan, Peru, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!