Low MOQ for Dia 550mm Graphite Electrode - UHP 700mm Graphite Electrode – Hexi

Low MOQ for Dia 550mm Graphite Electrode - UHP 700mm Graphite Electrode – Hexi Detail:

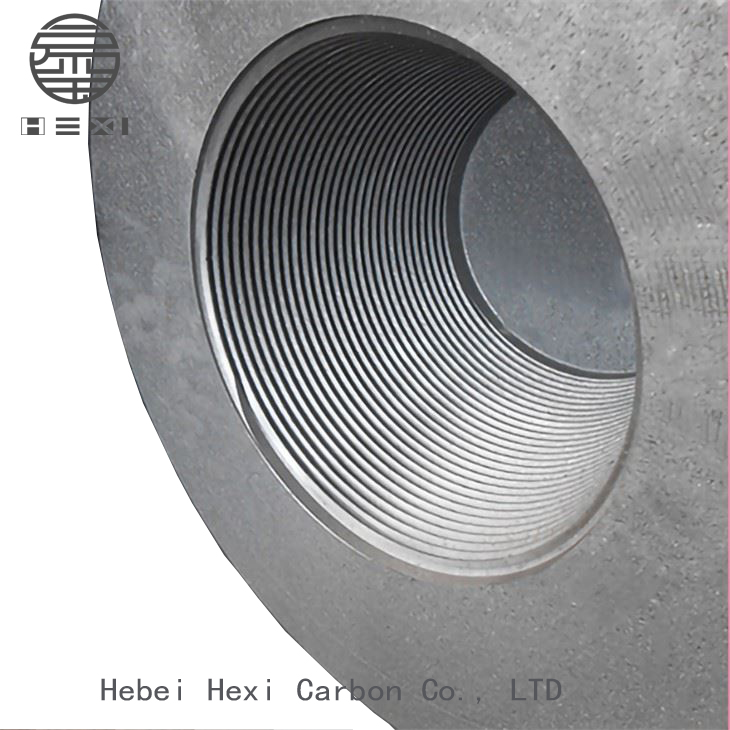

700mm UHP graphite electrode is made of high quality needlelike coke, which is formed, roasted, impregnated, graphitized and machineprocessed as a high quality conductive material for electric arc furnace. UHP 700mm graphite electrode, The allowable current capacity is 73000 ~ 96000A, the allowable current density is 18-24A/㎡ . It is designed for superpower electric arc furnace steelmaking.

Note: It is recommended that the current capacity be -10% for electric furnace and +10% for ladle furnace.

|

Allowable current load for ultra-high power graphite electrodes |

|||||

|

nominal diameter |

allowable current |

nominal diameter |

allowable current |

||

|

mm |

A |

A/㎡ |

mm |

A |

A/㎡ |

|

250 |

9000~14000 |

18~25 |

500 |

38000~55000 |

18~27 |

|

300 |

15000~22000 |

20~30 |

550 |

45000~65000 |

18~27 |

|

350 |

20000~30000 |

20~30 |

600 |

52000~78000 |

18~27 |

|

400 |

25000~40000 |

16~24 |

650 |

70000~86000 |

21~25 |

|

450 |

32000~45000 |

19~27 |

700 |

73000~96000 |

18~24 |

|

Ultra high power graphite electrode and joint standard |

|||||

|

items |

unit |

nominal diameter(mm) |

|||

|

250~400 |

450~550 |

600~700 |

|||

|

specific resistance |

electrode nipple |

μ Ω•m |

4.8~5.8 3.4~4.0 |

4.5~5.6 3.4~3.8 |

4.5~5.4 3.0~3.6 |

|

transverse strength |

electrode nipple |

MPa |

≥12.0 ≥22.0 |

≥12.0 ≥22.0 |

≥10.0 ≥24.0 |

|

elastic modulus |

electrode nipple |

GPa |

≤13.0 ≤18.0 |

≤13.0 ≤18.0 |

≤13.0 ≤20.0 |

|

ash content |

electrode nipple |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

bulk density |

electrode nipple |

g/m³ |

1.68~1.73 1.78~1.84 |

1.68~1.72 1.78~1.84 |

1.68~1.72 1.80~1.86 |

|

(C.T.E) |

electrode nipple |

10℃ |

≤1.2 ≤1.0 |

≤1.2 ≤1.0 |

≤1.2 ≤1.0 |

Product detail pictures:

Related Product Guide:

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for Low MOQ for Dia 550mm Graphite Electrode - UHP 700mm Graphite Electrode – Hexi, The product will supply to all over the world, such as: Egypt, Borussia Dortmund, Islamabad, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.