Low MOQ for Dia 550mm Graphite Electrode - 550mm high power graphite electrode – Hexi

Low MOQ for Dia 550mm Graphite Electrode - 550mm high power graphite electrode – Hexi Detail:

HP graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making.

Modern steelmaking methods mainly include converter steelmaking and electric furnace steelmaking. The most fundamental difference between the electric furnace steelmaking method and the converter steelmaking method is that the electric furnace steelmaking method uses electrical energy as a heat source, and the electric arc furnace steelmaking method is the most commonly used.

EAF steelmaking is based on the electric arc generated by the discharge between the electrode and the charge, which converts electrical energy into thermal energy in the arc light, and uses the direct action of radiation and arc to heat and melt the metal and slag to smelt steel and alloys of various compositions.

Typical Properties

| Comparison Technical Specification for HP Graphite Electrode 22″ | ||

| Electrode | ||

| Item | Unit | Supplier Spec |

| Typical Characteristics of Pole | ||

| Nominal Diameter | mm | 550 |

| Max Diameter | mm | 562 |

| Min Diameter | mm | 556 |

| Nominal Length | mm | 1800-2400 |

| Max Length | mm | 1900-2500 |

| Min Length | mm | 1700-2300 |

| Bulk Density | g/cm3 | 1.68-1.72 |

| transverse strength | MPa | ≥10.0 |

| Young’ Modulus | GPa | ≤12.0 |

| Specific Resistance | µΩm | 5.2-6.5 |

| Maximum current density | KA/cm2 | 14-22 |

| Current Carrying Capacity | A | 34000-53000 |

| (C.T.E) | 10-6℃ | ≤2.0 |

| ash content | % | ≤0.2 |

| Typical Characteristics of Nipple (4TPI/3TPI) | ||

| Bulk Density | g/cm3 | 1.78-1.83 |

| transverse strength | MPa | ≥22.0 |

| Young’ Modulus | GPa | ≤15.0 |

| Specific Resistance | µΩm | 3.2-4.3 |

| (C.T.E) | 10-6℃ | ≤1.8 |

| ash content | % | ≤0.2 |

Graphite electrode composition

1.Petroleum coke is black and porous, carbon is the main composition, and the ash content is very low, generally below 0.5%.

Petroleum coke can be divided into two types of raw coke and calcined coke according to the heat treatment temperature. The former contains a large amount of volatile matter and has low mechanical strength. The calcined coke is obtained by calcining the raw coke.

Petroleum coke can be divided into high sulfur coke (with sulfur content above 1.5%), medium sulfur coke (with sulfur content 0.5%-1.5%), and low sulfur coke (with sulfur content below 0.5%) according to sulfur level. Graphite electrodes and other artificial graphite products are generally produced using low sulfur coke.

2.Needle coke is a kind of high-quality coke with obvious fiber texture, particularly low thermal expansion coefficient and easy graphitization. Therefore, needle coke is a key raw material for manufacturing high-power or ultra-high-power graphite electrodes featured with low resistivity, small thermal expansion coefficient, and good thermal shock resistance.

3.Coal pitch is one of the main products of coal tar after deep processing. It is a mixture of multiple hydrocarbons. Coal pitch is used as a binder and impregnating material. Its performance has a great influence on the quality of graphite electrodes.

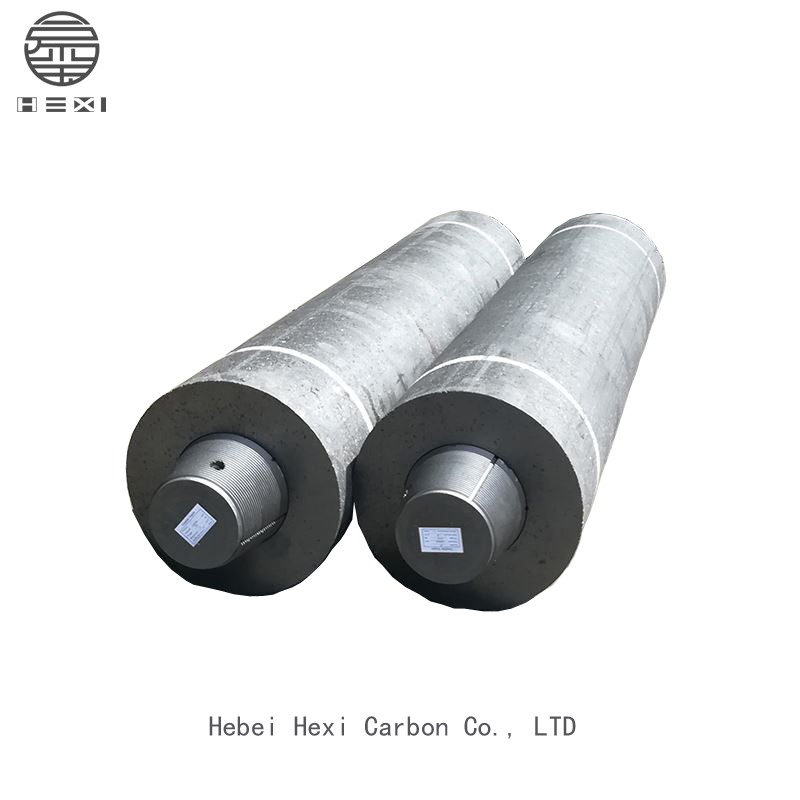

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Low MOQ for Dia 550mm Graphite Electrode - 550mm high power graphite electrode – Hexi, The product will supply to all over the world, such as: Danish, Singapore, San Francisco, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.