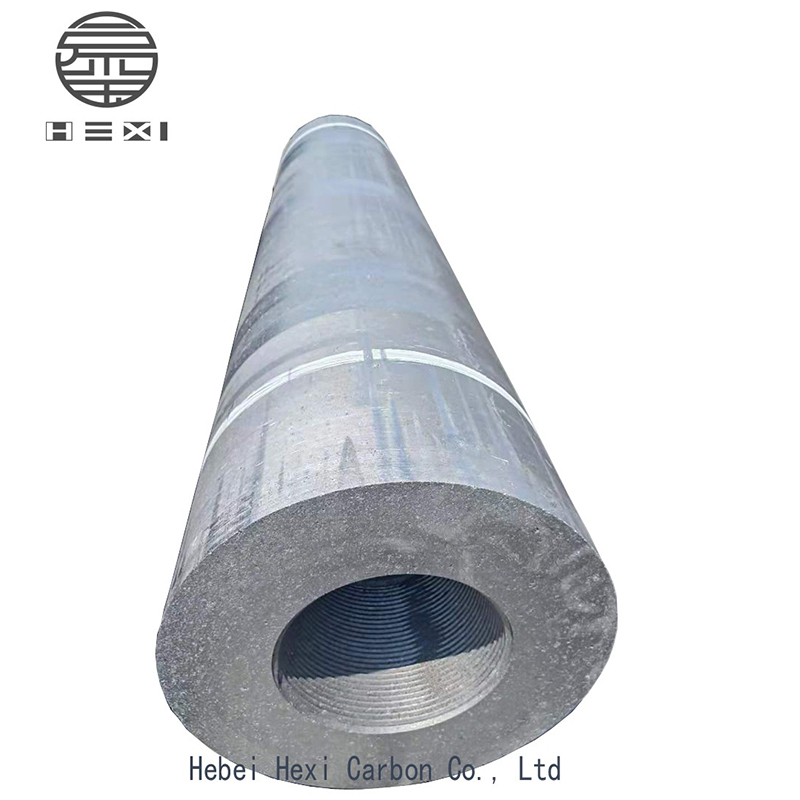

Hot-selling Industry Graphite Electrode - 600mm high power graphite electrode – Hexi

Hot-selling Industry Graphite Electrode - 600mm high power graphite electrode – Hexi Detail:

Grade:High Power

Applicable furnace: EAF

Length: 2100mm/2400mm/2700mm

Nipple:3TPI/4TPI

Payment: T/T, L/C

Shipping Term: EXW/FOB/CIF

MOQ:10TON

|

Typical Properties of Graphite Electrode |

|

|

|

|

|

|

Properties |

Position |

Unit |

UHP |

HP |

|

|

300-600mm |

650-800mm |

300-800mm |

|

|

|

|

Specific Resistance |

Body |

μΩm |

4.8-5.8 |

4.6-5.8 |

5.8-6.6 |

|

Nipple |

3.8-4.5 |

3.8-4.5 |

4.2-5.0 |

|

|

|

Bending Strength |

Body |

Mpa |

10.0-14.0 |

10.0-14.0 |

10.0-13.0 |

|

Nipple |

20.0-26.0 |

20.0-26.0 |

18.0-22.0 |

|

|

|

Young’s Modulus |

Body |

Gpa |

9.0-13.0 |

10.0-14.0 |

8.0-12.0 |

|

Nipple |

15.0-18.0 |

15.0-18.0 |

14.0-16.0 |

|

|

|

Bulk Density |

Body |

g/cm3 |

1.68-1.74 |

1.70-1.74 |

1.62-1.66 |

|

Nipple |

1.77-1.82 |

1.78-1.84 |

1.74-1.80 |

|

|

|

CTE(100-600°C) |

Body |

×10 -6/゚C |

1.1-1.4 |

1.1-1.4 |

1.6-1.9 |

|

Nipple |

0.9-1.2 |

0.9-1.2 |

1.1-1.4 |

|

|

|

Ash Content |

% |

0.3 |

0.3 |

0.3 |

|

Compared with copper, graphite has advantages such as less consumption, faster discharge rate, lighter weight and smaller thermal expansion coefficient, so it gradually replaces copper electrode to become the mainstream of discharge processing materials. According to the capacity of the electric furnace, graphite electrodes of different diameters are used. For continuous use of the electrodes, the electrodes are connected by the threaded joint of the electrodes. The graphite electrodes used in steel making account for about 70-80% of the total consumption of the graphite electrodes.

Graphite electrode consumption and breakage is common in practice. What causes these? Here is the analysis for reference.

|

Factors |

Body Breakage |

Nipple Breakage |

Loosening |

Spalling |

Electtode Loss |

Oxidation |

Electorde Consumption |

|

Non-conductors in charge |

◆ |

◆ |

|

|

|

|

|

|

Heavy scrap in charge |

◆ |

◆ |

|

|

|

|

|

|

Transformer overcapacity |

◆ |

◆ |

|

◆ |

◆ |

◆ |

◆ |

|

Three phase imbalance |

◆ |

◆ |

|

◆ |

◆ |

|

◆ |

|

Phase Rotation |

|

◆ |

◆ |

|

|

|

|

|

Excessive Vibration |

◆ |

◆ |

◆ |

|

|

|

|

|

Clamper Pressure |

◆ |

|

◆ |

|

|

|

|

|

Roof electrode socket not align with electrode |

◆ |

◆ |

|

|

|

|

|

|

Cooling water sprayed on electrodes above roof |

|

|

|

|

|

|

△ |

|

Scrap preheating |

|

|

|

|

|

|

△ |

|

Secondary voltage too high |

◆ |

◆ |

|

◆ |

◆ |

|

◆ |

|

Secondary current too high |

◆ |

◆ |

|

◆ |

◆ |

◆ |

◆ |

|

Power too low |

◆ |

◆ |

|

◆ |

◆ |

|

◆ |

|

Oil consumption too high |

|

|

|

◆ |

◆ |

|

◆ |

|

Oxygen Consumption too high |

|

|

|

◆ |

◆ |

|

◆ |

|

long time heating |

|

|

|

|

|

|

◆ |

|

Electrode dipping |

|

|

|

|

◆ |

|

◆ |

|

Dirty connection part |

|

◆ |

◆ |

|

|

|

|

|

Poor maintenance for lift plugs and tightening tools |

|

◆ |

◆ |

|

|

|

|

|

Insufficient connection |

|

◆ |

◆ |

|

|

|

|

◆ Stands for being good factors

△ Stands for being bad factors

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We've been an energetic corporation with wide market for Hot-selling Industry Graphite Electrode - 600mm high power graphite electrode – Hexi, The product will supply to all over the world, such as: luzern, Russia, San Diego, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will probably be more conveniently to service our customers.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.