Good User Reputation for Graphite Electrode Dia 75mm - Regular Power Graphite Electrode – Hexi

Good User Reputation for Graphite Electrode Dia 75mm - Regular Power Graphite Electrode – Hexi Detail:

The main raw material of ordinary power graphite electrode body is high-quality petroleum coke, which is mainly used in electric arc furnace for steelmaking. The production process includes calcination, batching, kneading, forming, roasting, graphitization and machining. The raw materials of nipple are needle coke and high-quality petroleum coke, and the production process includes one impregnation and two roasting.

Hexi Carbon is a manufacturing company that produces, sells, exports and provides graphite electrodes for wide application.

Our ordinary power graphite electrode is mainly used for electric arc furnace steelmaking. Our price is fair and competitive. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Used Of Resistance Furnace

the graphitizing furnace for graphite products used in the production of resistance furnaces, the melting furnace and production of technical glass, and the electric furnace for Silicon Carbide are resistance furnaces, and the material management in the furnace is both a heating resistance and a heat resistance, another subject to be heated up.

Processed Product

a large number of graphite electrode blanks are also used for processing various kinds of shaped products such as crucible, graphite boat, hot-pressing casting mould and heating body of vacuum electric furnace. It should also be noted that in the graphite materials including the graphite electrode, the graphite mold and the graphite crucible three kinds of high temperature composite materials, the graphite is easy to oxidize the combustion reaction under the high temperature, thus on the surface of the plastic material the carbon layer increases the porosity of the porous structure.

The standard of regular power graphite electrode and nipple

RP Graphite electrode Permissible current load

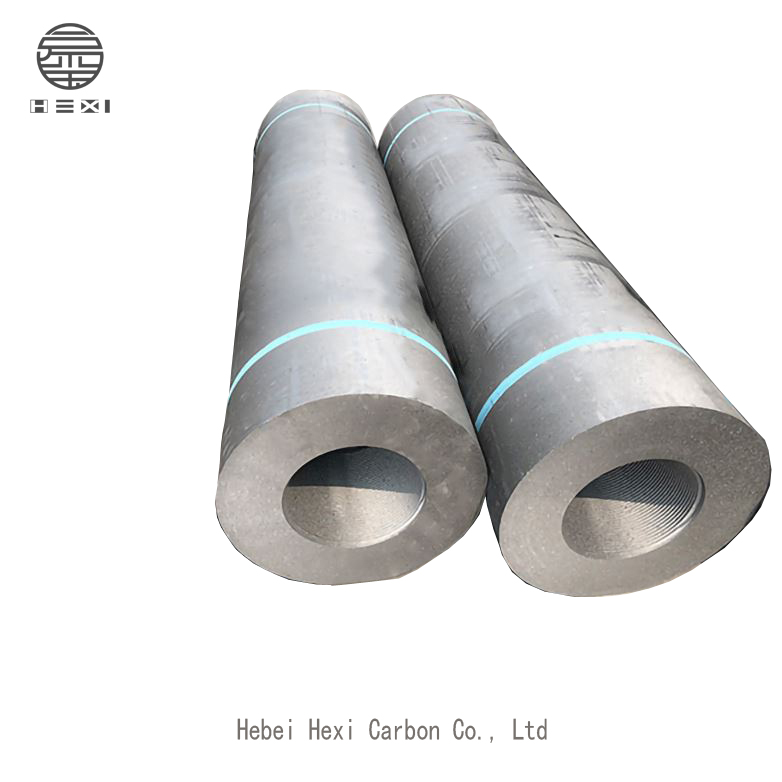

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Good User Reputation for Graphite Electrode Dia 75mm - Regular Power Graphite Electrode – Hexi, The product will supply to all over the world, such as: Portland, Uruguay, Cyprus, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!