Free sample for Ladle Furnace Graphite Electrode - Ultra High Power Graphite Electrode – Hexi

Free sample for Ladle Furnace Graphite Electrode - Ultra High Power Graphite Electrode – Hexi Detail:

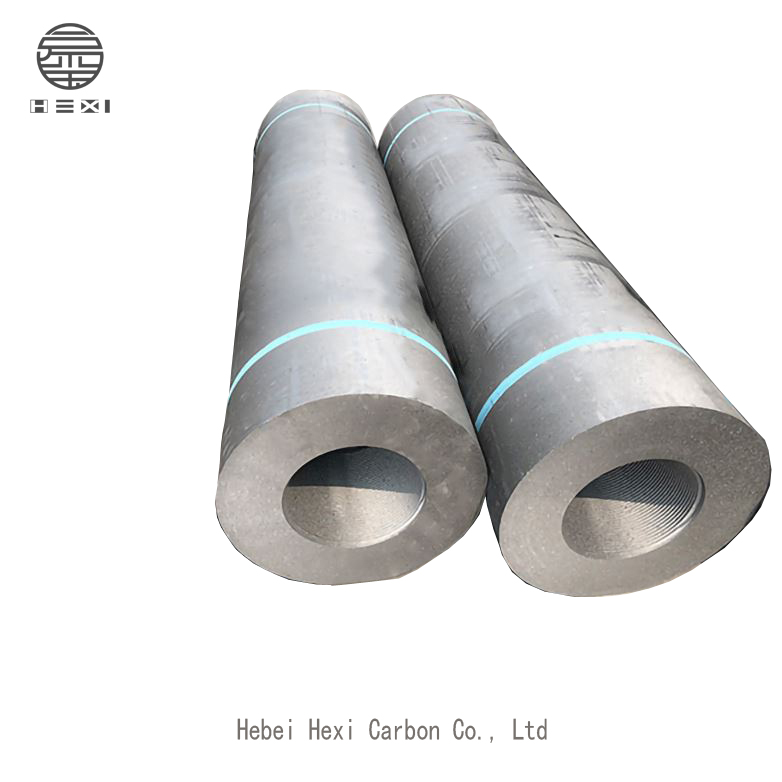

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking.

The standard of ultra-high power graphite electrode and nipple

UHP Graphite electrode Permissible current load

Ultra-high-power graphite electrode produced by Hexin Carbon is produced by high-grade needle coke, and its graphitization heat treatment is carried out in an internal series graphitization furnace, and the graphitization temperature is as high as 2800〜3000°C, so the resistivity is lower, allowing a larger current density, a smaller linear expansion coefficient and excellent thermal shock resistance. It is a special ultra-high power graphite electrode for electric arc furnace and ladle refining furnace. The ultra-high power graphite electrode of Hexi Carbon Company adopts the most advanced technology and is produced in strict accordance with the global standards, which basically meets the world-class quality standards. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Product detail pictures:

Related Product Guide:

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Free sample for Ladle Furnace Graphite Electrode - Ultra High Power Graphite Electrode – Hexi, The product will supply to all over the world, such as: Rio de Janeiro, Qatar, Puerto Rico, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.