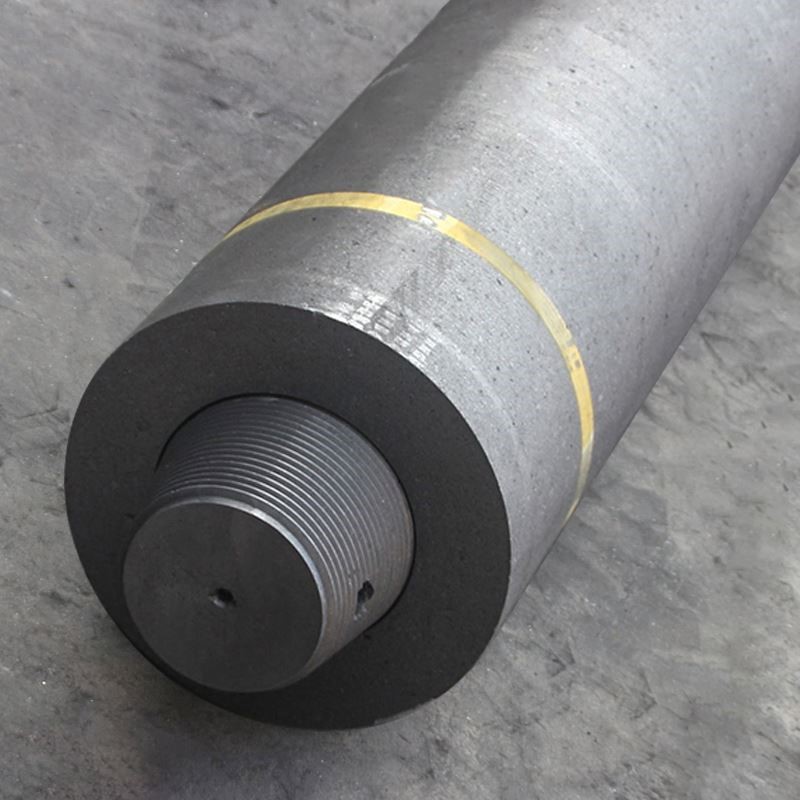

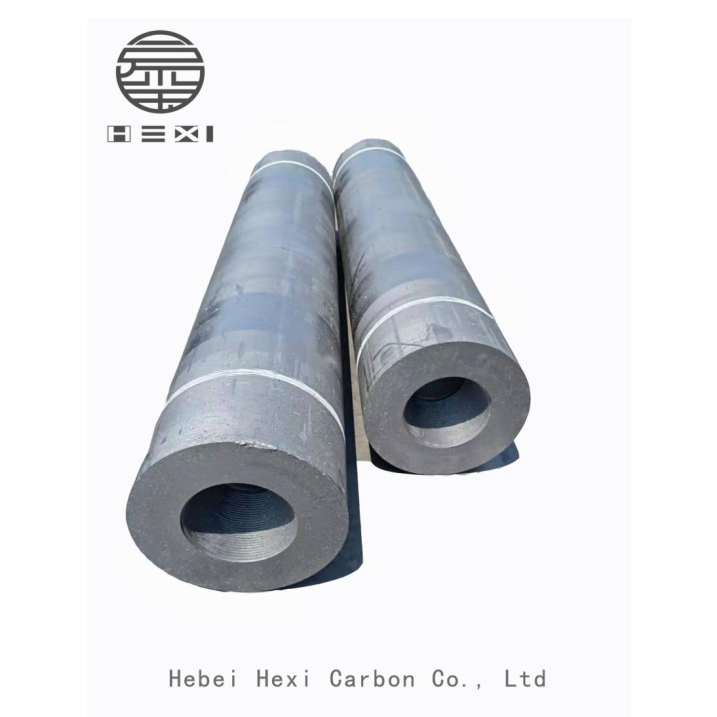

Fixed Competitive Price Graphite Electrode Uhp For Eaf - RP 350 Ordinary power graphite electrode – Hexi

Fixed Competitive Price Graphite Electrode Uhp For Eaf - RP 350 Ordinary power graphite electrode – Hexi Detail:

|

The products of Hexi have passed ISO9001 quality management system certification and obtained the export qualification of graphite electrode authorized by Chinese government. With good quality and excellent after-sales service, our products are in great demand in the world market.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Graphitization refers to the high temperature heat treatment process of transforming amorphous carbon into three-dimensional ordered planar hexagonal mesh laminated graphite by heating carbon products to 2300℃ or above in a high temperature electric furnace. The graphitization of carbon materials is carried out at a high temperature of 2300 ~ 3000℃. Because the combustion of fossil fuels is difficult to obtain such a high temperature, it can only be achieved by electric heating roasting in industry.

Product detail pictures:

Related Product Guide:

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for Fixed Competitive Price Graphite Electrode Uhp For Eaf - RP 350 Ordinary power graphite electrode – Hexi, The product will supply to all over the world, such as: Southampton, Estonia, Singapore, If you need to have any of our merchandise, or have other items to be produced, make sure you send us your inquiries, samples or in depth drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.