-

OEM Supply Uhp Graphite Electrode 300mm - 550mm high power graphite electrode – Hexi

HP graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making. Modern steelmaking methods mainly include converter steelmaking and electric furnace steelmaking. The most fundamental difference between the electric furnace steelmaking method and the converter steelmaking method is that the electric furnace steelmaking method uses electrical energy as a heat source... -

OEM Factory for Graphite Electrode For Arc Furnaces - UHP 500mm Graphite Electrode – Hexi

Graphite electrode is the only material that can withstand high temperatures up to 3000 degrees Celsius without being deformed and melted. So, they are chosen to make steel in electric arc furnaces (EAF) and ladle furnaces (LF). How does it work in practice? While electrical current passing through the electrode, the electrode tips create an electric arc which generates extremely high heat and melts the steel into molten iron. High temperature resistance and thermal shock resistance makes it ... -

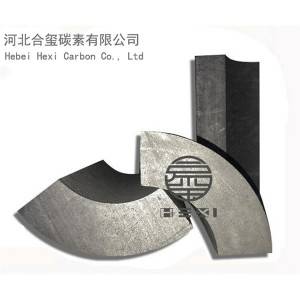

2021 wholesale price Graphite Trapezoidal Brick - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace.Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our ... -

OEM Manufacturer Eaf Graphite Electrode Groove - Graphite Rod & Carbon Rod – Hexi

Graphite rods produced by Hexi Carbon Company have good electrical conductivity, thermal conductivity, lubricity and chemical stability. Graphite rods are easy to process and cheap, and can be used in various applications: machinery, metallurgy, chemical industry, casting, nonferrous alloys, ceramics, semiconductors, medicine, environmental protection and so on. Most graphite rods produced by our company are used by customers for electric heating components in high temperature vacuum furnaces... -

OEM/ODM Supplier Graphite Electrode Uhp 600 - 400mm high power graphite electrode – Hexi

HP 400mm graphite electrode is mainly made of petroleum coke and needle coke. The allowable current is 21000-31000A, and the current density can be 16-24A/cm². Generally used for high-power electric arc furnace steelmaking. The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes... -

Rapid Delivery for Carbon Graphite Fine Powder - Graphite Block & Graphite Cube – Hexi

The production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to ... -

Good Wholesale Vendors All Sizes Of Graphite Electrodes - 500mm Graphite Electrodes with Nipples – Hexi

The oxidation resistance is good, and the electrode consumption is significantly reduced. Selected high quality raw materials, graphitization at high temperature, low content of impurities The 500mmRP graphite electrode produced by China Hexi Carbon Co., Ltd. has a low resistivity,good conductivity,high thermal conversion rate, high node efficiency, oxidation resistance and low electrode consumption. They use high quality raw materials, with low content of impurities. The comprehensive therma... -

Factory Price Graphite Electrode Uhp - 500mm high power graphite electrode – Hexi

HP and UHP series of graphite electrode are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace. HP 500mm graphite electrodes are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace. The loss of graphite electrodes in electric furnace steelmaking is very common, what are they and what is it rel... -

Low price for Graphite Rod For Casting - Graphite Crucible – Hexi

Hexi carbon mainly produces graphite electrodes. Besides graphite electrodes, we also produce some graphite products. The manufacturing process of these graphite products has the same process and quality inspection as graphite electrodes. Our graphite products mainly include graphite crucible, graphite cube, graphite rod and carbon rod, etc. Customers can customize graphite products with different shapes according to their needs. The production process of graphite products is to mix petroleum... -

Competitive Price for Fine Graphite Powder - Graphite Crucible – Hexi

Hexi carbon mainly produces graphite electrodes. Besides graphite electrodes, we also produce some graphite products. The manufacturing process of these graphite products has the same process and quality inspection as graphite electrodes. Our graphite products mainly include graphite crucible, graphite cube, graphite rod and carbon rod, etc. Customers can customize graphite products with different shapes according to their needs. The production process of graphite products is to mix petroleum... -

Europe style for Carbon Refractory Graphite Electrode - UHP 450mm Graphite Electrode – Hexi

Graphite electrodes play an important role in steelmaking industry, they are often used to melt the scrap in electric arc furnaces(abbreviated as EAF) . There are some key properties which determine the quality of electrode, what are they? The coefficient of thermal expansion (abbreviated as CTE) refers to a measure of the degree of expansion of a material after being heated, when the temperature increases by 1°C, it causes the expansion degree of solid material sample in a specific direction... -

OEM Factory for Graphite Electrode For Arc Furnaces - Graphite Electrode Joint – Hexi

Graphite electrode joint is an accessory of graphite electrode, which is used together with graphite electrode. When it is used, it needs to be connected with the screw thread of graphite electrode female head. Graphite electrode joint plays a very important role in steel-making, which directly affects the function of graphite electrode. If there is no high-quality joint, graphite electrode will be easily broken and loose, resulting in accidents. Therefore, the state has national industry sta...