-

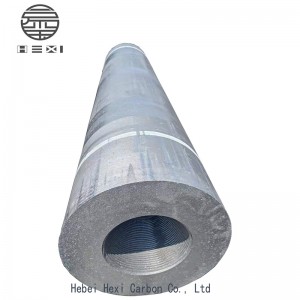

Competitive Price for Graphite Electrodes With Cylindrical Nipples - UHP 550mm Graphite Electrode – Hexi

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure. What’s the funtion of graphitization? *Improve the electrical and thermal conductivity *Improve the thermal shock resistance and chemical stability (the linear expansion c... -

OEM Customized Ultra High Power Graphite Electrode - UHP 450mm Graphite Electrode – Hexi

Graphite electrodes play an important role in steelmaking industry, they are often used to melt the scrap in electric arc furnaces(abbreviated as EAF) . There are some key properties which determine the quality of electrode, what are they? The coefficient of thermal expansion (abbreviated as CTE) refers to a measure of the degree of expansion of a material after being heated, when the temperature increases by 1°C, it causes the expansion degree of solid material sample in a specific direction... -

Hot sale Factory Steel Making Graphite Electrode - UHP 550mm Graphite Electrode – Hexi

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure. What’s the funtion of graphitization? *Improve the electrical and thermal conductivity *Improve the thermal shock resistance and chemical stability (the linear expansion c... -

OEM manufacturer Carbon Electrode Graphite - UHP 550mm Graphite Electrode – Hexi

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure. What’s the funtion of graphitization? *Improve the electrical and thermal conductivity *Improve the thermal shock resistance and chemical stability (the linear expansion c... -

New Fashion Design for Uhp Graphite Electrode 450 - RP 550mm Graphite Electrode – Hexi

This kind of graphite electrode is mainly made of petroleum coke. It is allowed to carry the current density less than 12~14A/㎡. Generally it is used in regular power electric arc furnace for steel making, silicon making, yellow phosphorus making etc. Application Graphite electrodes are widely used for production of alloy steels, metal and other nonmetallic materials. * DC or AC electric arc furnace. * Submerged arc furnace(abbreviated as SAF). * Ladle furnace. Certificates Our products... -

China OEM Hp Graphite Electrodes Nipples - Regular Power Graphite Electrode – Hexi

The main raw material of ordinary power graphite electrode body is high-quality petroleum coke, which is mainly used in electric arc furnace for steelmaking. The production process includes calcination, batching, kneading, forming, roasting, graphitization and machining. The raw materials of nipple are needle coke and high-quality petroleum coke, and the production process includes one impregnation and two roasting. Hexi Carbon is a manufacturing company that produces, sells, exports and pro... -

factory customized Graphite Electrode Uhp Nipples - 400mm high power graphite electrode – Hexi

HP 400mm graphite electrode is mainly made of petroleum coke and needle coke. The allowable current is 21000-31000A, and the current density can be 16-24A/cm². Generally used for high-power electric arc furnace steelmaking. The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes... -

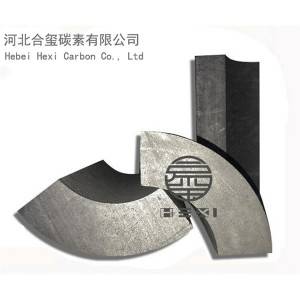

PriceList for Graphite Rod Blanks - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace.Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our ... -

Massive Selection for Super Fine Graphite Powder - Graphite Rod & Carbon Rod – Hexi

Graphite rods produced by Hexi Carbon Company have good electrical conductivity, thermal conductivity, lubricity and chemical stability. Graphite rods are easy to process and cheap, and can be used in various applications: machinery, metallurgy, chemical industry, casting, nonferrous alloys, ceramics, semiconductors, medicine, environmental protection and so on. Most graphite rods produced by our company are used by customers for electric heating components in high temperature vacuum furnaces... -

China Supplier Graphite Electrode And Carbon - HP 300mm Graphite Electrode – Hexi

HP 300mm graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making. HP 300mm graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making.The length could be from 1500mm to 2100mm at your option. Properties and dimensions Part Resi... -

High reputation 350mm Graphite Electrode - 450mm high power graphite electrod – Hexi

HP graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making. Typical Properties Properties Position Unit HP 300-800mm Specific Rresistance body μΩm 5.8-6.6 nipple 4.2-5.0 Bendin Strengh body mpa 10.0-13.0 nipple 18.0-22.0 Young’s Modulus body cpa 8.0-12.0 nipple 14.0-16.0 Bulk Density ... -

Chinese Professional Small Diameter Graphite Electrode - HP 400mm graphite electrode – Hexi

The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing. High power graphite electrode and joint standard items unit nominal diameter(mm) 200~400 450~...