-

Manufacturer of Uhp Graphite groove - Graphite Block & Graphite Cube – Hexi

The production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to ... -

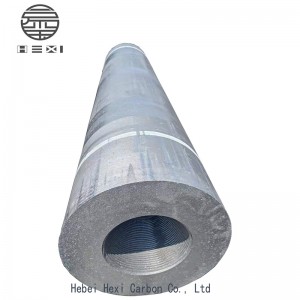

High Quality for Steel Melt Graphite Electrode - 450mm high power graphite electrod – Hexi

HP graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making. Typical Properties Properties Position Unit HP 300-800mm Specific Rresistance body μΩm 5.8-6.6 nipple 4.2-5.0 Bendin Strengh body mpa 10.0-13.0 nipple 18.0-22.0 Young’s Modulus body cpa 8.0-12.0 nipple 14.0-16.0 Bulk Density ... -

Ordinary Discount Graphite Electrode Uhp Grade - 400mm high power graphite electrode – Hexi

HP 400mm graphite electrode is mainly made of petroleum coke and needle coke. The allowable current is 21000-31000A, and the current density can be 16-24A/cm². Generally used for high-power electric arc furnace steelmaking. The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes... -

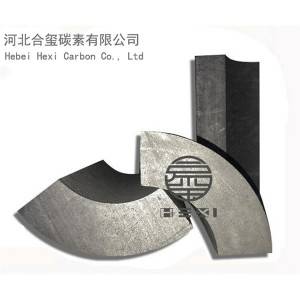

OEM manufacturer Graphite Blanks - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace.Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our ... -

Big Discount Spectral Graphite Electrode Rod - RP 450mm Graphite Electrode – Hexi

The main raw material of graphite electrode production is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electrode. The main raw material of this kind of RP 450mm Graphite Electrode is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electrode. The sulfur content of petroleum coke and asphalt coke should not exceed 0.5%. Needle coke is also needed to produce high power or ultra high power graphite electrodes. In add... -

Lowest Price for Pyrolytic Graphite Rod - Graphite Crucible – Hexi

Hexi carbon mainly produces graphite electrodes. Besides graphite electrodes, we also produce some graphite products. The manufacturing process of these graphite products has the same process and quality inspection as graphite electrodes. Our graphite products mainly include graphite crucible, graphite cube, graphite rod and carbon rod, etc. Customers can customize graphite products with different shapes according to their needs. The production process of graphite products is to mix petroleum... -

Top Quality Shp Uhp Graphite Electrode - 500mm high power graphite electrode – Hexi

HP and UHP series of graphite electrode are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace. HP 500mm graphite electrodes are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace. The loss of graphite electrodes in electric furnace steelmaking is very common, what are they and what is it rel... -

Best quality Baked Graphite Electrode - 500mm high power graphite electrode – Hexi

HP and UHP series of graphite electrode are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace. HP 500mm graphite electrodes are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace. The loss of graphite electrodes in electric furnace steelmaking is very common, what are they and what is it rel... -

Wholesale 400mm Graphite Electrode - HP 400mm graphite electrode – Hexi

The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing. High power graphite electrode and joint standard items unit nominal diameter(mm) 200~400 450~... -

Big discounting Graphite Arc Electrode - RP 450mm Graphite Electrode – Hexi

The main raw material of graphite electrode production is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electrode. The main raw material of this kind of RP 450mm Graphite Electrode is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electrode. The sulfur content of petroleum coke and asphalt coke should not exceed 0.5%. Needle coke is also needed to produce high power or ultra high power graphite electrodes. In add... -

OEM Factory for Graphite Electrode For Arc Furnaces - UHP 550mm Graphite Electrode – Hexi

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure. What’s the funtion of graphitization? *Improve the electrical and thermal conductivity *Improve the thermal shock resistance and chemical stability (the linear expansion c... -

Fast delivery Graphite Arc Furnaces lining - Graphite Block & Graphite Cube – Hexi

The production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to ...