-

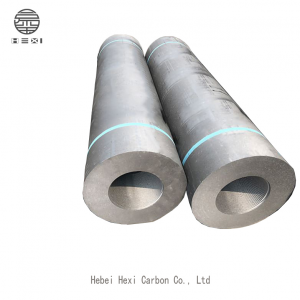

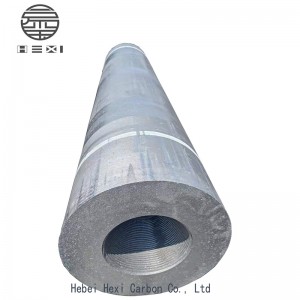

Factory Free sample 4tpi Nipples Graphite Electrode - UHP 700mm Graphite Electrode – Hexi

700mm UHP graphite electrode is made of high quality needlelike coke, which is formed, roasted, impregnated, graphitized and machineprocessed as a high quality conductive material for electric arc furnace. UHP 700mm graphite electrode, The allowable current capacity is 73000 ~ 96000A, the allowable current density is 18-24A/㎡ . It is designed for superpower electric arc furnace steelmaking. Note: It is recommended that the current capacity be -10% for electric furnace and +10% for ladle f... -

Manufactur standard Eaf Graphite Electrode - HP 400mm graphite electrode – Hexi

The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing.Hexi Carbon is a manufacturing company that produces, sells, exports and provides a wide range of high-power graphit... -

Factory Price For Uhp Graphite Electrodes With Nipples - UHP 350mm Graphite Electrode – Hexi

UHP 350mm Graphite Electrode is made of petroleum coke, needle coke, and bonding coal pitch. Its production process is: calcining, dosing, mixing, forming, baking and impregnation, graphitization in a high temperature of over 3000°C, then precision machining. Comparison Technical Specification for UHP Graphite Electrode 14″ Electrode Item Unit Supplier Spec Typical Characteristics of Pole Nominal Diameter mm 300 Max Diameter mm 358 Min Diameter mm 352 Nominal Lengt... -

Manufacturer for Low Specific Resistance Graphite Electrode - UHP 450mm Graphite Electrode – Hexi

Graphite electrodes play an important role in steelmaking industry, they are often used to melt the scrap in electric arc furnaces(abbreviated as EAF) . There are some key properties which determine the quality of electrode, what are they? The coefficient of thermal expansion (abbreviated as CTE) refers to a measure of the degree of expansion of a material after being heated, when the temperature increases by 1°C, it causes the expansion degree of solid material sample in a specific direction... -

OEM Factory for Graphite Electrode For Eaf Lf - 450mm high power graphite electrod – Hexi

HP graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making. Comparison Technical Specification for HP Graphite Electrode 18″ Electrode Item Unit Supplier Spec Typical Characteristics of Pole Nominal Diameter mm 450 Max Diameter mm 460 Min Diameter mm 454 Nominal Length mm 1800-2400 Max Length mm 1900-2500 Min Length mm 170... -

Special Price for High Purity Graphite Block - Chinese Graphite Block – Hexi

The production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to ... -

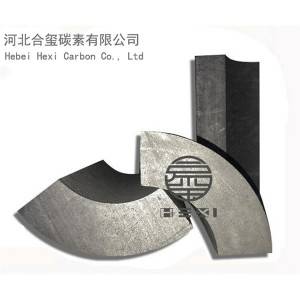

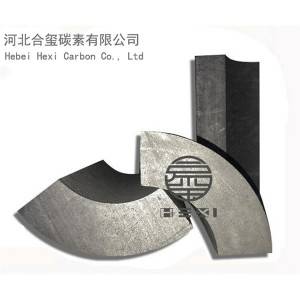

Bottom price Regular Graphite plate - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace.Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our ... -

Factory Outlets Graphite Rod Electrode 6 Mm - 300mm UHP Electrode – Hexi

Application Graphite electrodes are widely used for production of alloy steels, metal and other nonmetallic materials, etc. * DC electric arc furnace. * AC electric arc furnace. * Submerged arc furnace. * Ladle furnace. Comparison Technical Specification for UHP Graphite Electrode 12″ Electrode Item Unit Supplier Spec Typical Characteristics of Pole Nominal Diameter mm 300 Max Diameter mm 307 Min Diameter mm 299 Nominal Length mm 1600/1800 Max Length mm 1700/... -

Factory Price Graphite Electrode Uhp - 600 UHP graphite electrode – Hexi

Compared with HP and RP electrodes, UHP graphite electrodes have more advantages as follows: *Lower electrical resistivity, the lower the resistivity, the better the conductivity and consumption *Heat tolerance and oxidation resistance, reducing physical and chemical loss in practice, especially at high temperature in practice. *Smaller coefficient of thermal expansion,the lower the coefficient, the stronger the thermal stability of the product and the higher the oxidation resistance. *Low as... -

18 Years Factory Dry Graphite Powder - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace.Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our ... -

18 Years Factory Graphite Electrode For Refining Furnace - 600 UHP graphite electrode – Hexi

Compared with HP and RP electrodes, UHP graphite electrodes have more advantages as follows: *Lower electrical resistivity, the lower the resistivity, the better the conductivity and consumption *Heat tolerance and oxidation resistance, reducing physical and chemical loss in practice, especially at high temperature in practice. *Smaller coefficient of thermal expansion,the lower the coefficient, the stronger the thermal stability of the product and the higher the oxidation resistance. *Low as... -

Hot-selling Thread Electrode - Chinese Graphite Block – Hexi

The production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to ...