-

OEM/ODM Supplier Rp Graphite Electrode 200mm - High Power Graphite electrode – Hexi

High-power graphite electrodes are produced from high-quality petroleum coke (or low-grade needle coke). The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing. The raw material of nipple is imported oil needle coke, and the production process includes twice dipping and three baking. Its physical and mechanical properties are higher than those of ordinary power graphite electrodes, such as lower resistivity an... -

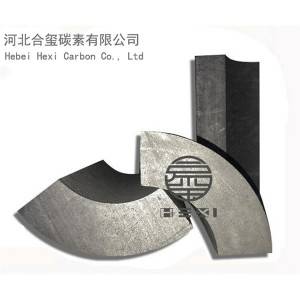

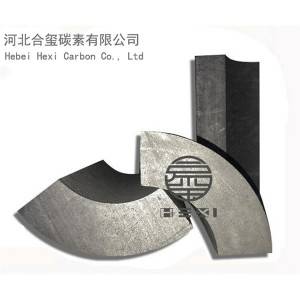

Fixed Competitive Price Expanded Graphite Powder - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace. Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our... -

OEM Customized Electrode Block - Graphite Block & Graphite Cube – Hexi

TThe production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to... -

professional factory for Graphite Electrodes With Nipples - Ultra High Power Graphite Electrode – Hexi

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking. Used In Arc Steel-Making Furnace the graphite electrode material used for electric arc steelmaking furnace is mainly ... -

Good Quality Carburizer – Carburizer – Hexi

Artificial graphite powder, natural graphite powder and graphite scrap can be used as carburizing agent. We mainly produce artificial graphite powder and graphite scrap 1、Synthetic graphite powder, also known as artificial graphite, is produced during the processing of graphite electrode and belongs to its by-product. In addition, graphite powder can be obtained by calcining petroleum coke powder at a certain temperature and then graphitizing it. Graphite powder has superior performance, wid... -

OEM/ODM China Graphite Electrode 450mm - High Power Graphite electrode – Hexi

High-power graphite electrodes are produced from high-quality petroleum coke (or low-grade needle coke). The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing. The raw material of nipple is imported oil needle coke, and the production process includes twice dipping and three baking. Its physical and mechanical properties are higher than those of ordinary power graphite electrodes, such as lower resistivity an... -

Short Lead Time for Graphite Oxide Powder - Graphite Tile – Hexi

Graphite tile is designed and reformed by Hexi Company for the defects of high cost and short service life of copper head electric tile in electric furnace. Graphite conductive tile is used instead of copper head electric tile and applied in 6.3 MVA electric furnace. As a result, its service life is long, the number of hot stops of the furnace is significantly reduced, and the production cost is greatly reduced. Graphite tile is named after its shape, which is similar to the tile used in our... -

Competitive Price for Graphite Electrodes With Cylindrical Nipples - Regular Power Graphite Electrode – Hexi

The main raw material of ordinary power graphite electrode body is high-quality petroleum coke, which is mainly used in electric arc furnace for steelmaking. The production process includes calcination, batching, kneading, forming, roasting, graphitization and machining. The raw materials of nipple are needle coke and high-quality petroleum coke, and the production process includes one impregnation and two roasting. Hexi Carbon is a manufacturing company that produces, sells, exports and pro... -

Best Price for Graphite Poles - Graphite Rod & Carbon Rod – Hexi

Graphite rods produced by Hexi Carbon Company have good electrical conductivity, thermal conductivity, lubricity and chemical stability. Graphite rods are easy to process and cheap, and can be used in various applications: machinery, metallurgy, chemical industry, casting, nonferrous alloys, ceramics, semiconductors, medicine, environmental protection and so on. Most graphite rods produced by our company are used by customers for electric heating components in high temperature vacuum furnaces... -

Manufacturer for Low Specific Resistance Graphite Electrode - Graphite Electrode Joint – Hexi

Graphite electrode joint is an accessory of graphite electrode, which is used together with graphite electrode. When it is used, it needs to be connected with the screw thread of graphite electrode female head. Graphite electrode joint plays a very important role in steel-making, which directly affects the function of graphite electrode. If there is no high-quality joint, graphite electrode will be easily broken and loose, resulting in accidents. Therefore, the state has national industry sta... -

Quality Inspection for Graphite Electrodes - Ultra High Power Graphite Electrode – Hexi

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking. Used In Arc Steel-Making Furnace the graphite electrode material used for electric arc steelmaking furnace is mainly ... -

Factory Cheap Hot Uhp Grade Carbon Graphite Electrodes - Graphite Electrode Joint – Hexi

Graphite electrode joint is an accessory of graphite electrode, which is used together with graphite electrode. When it is used, it needs to be connected with the screw thread of graphite electrode female head. Graphite electrode joint plays a very important role in steel-making, which directly affects the function of graphite electrode. If there is no high-quality joint, graphite electrode will be easily broken and loose, resulting in accidents. Therefore, the state has national industry sta...