Factory wholesale High Power Graphite Electrode - 400 UHP graphite electrode – Hexi

Factory wholesale High Power Graphite Electrode - 400 UHP graphite electrode – Hexi Detail:

Graphite electrodes are mainly used in the steelmaking process. Iron scrap gets melted in an electric arc furnace and recycled. As a kind of conductor, they are an essential component in this kind of

UHP graphite electrode is mainly made up of high-quality needle coke,and widely used in ultra high power electric arc furnaces.It is capable of carrying the current density more than 25A/cm2

| Comparison Technical Specification for UHP Graphite Electrode 16″ | ||

| Electrode | ||

| Item | Unit | Supplier Spec |

| Typical Characteristics of Pole | ||

| Nominal Diameter | mm | 400 |

| Max Diameter | mm | 409 |

| Min Diameter | mm | 403 |

| Nominal Length | mm | 1600/1800 |

| Max Length | mm | 1700/1900 |

| Min Length | mm | 1500/1700 |

| Bulk Density | g/cm3 | 1.68-1.73 |

| transverse strength | MPa | ≥12.0 |

| Young’ Modulus | GPa | ≤13.0 |

| Specific Resistance | µΩm | 4.8-5.8 |

| Maximum current density | KA/cm2 | 16-24 |

| Current Carrying Capacity | A | 25000-40000 |

| (C.T.E) | 10-6℃ | ≤1.2 |

| ash content | % | ≤0.2 |

| Typical Characteristics of Nipple (4TPI) | ||

| Bulk Density | g/cm3 | 1.78-1.84 |

| transverse strength | MPa | ≥22.0 |

| Young’ Modulus | GPa | ≤18.0 |

| Specific Resistance | µΩm | 3.4~4.0 |

| (C.T.E) | 10-6℃ | ≤1.0 |

| ash content | % | ≤0.2 |

Manufacturing process

Graphite electrode is mainly made of petroleum coke and needle coke, mixed with coal pitch, getting through processes of calcinations, kneading, forming, baking, graphitizing and machining, finally to be products. Here are some explanations for some production process:

Kneading: Stirring and mixing a certain amount of carbon particles and powder with a certain amount of binder at a certain temperature, this process is called kneading.

The function of kneading

①Mix all kinds of raw materials evenly, and at the same time make solid carbon materials of different particle sizes uniformly mix and fill, and improve the density of the mixture;

②After adding coal asphalt, get all material firmly together.

③Some coal pitches penetrate into the internal voids, which further improves the density and adhesion of the paste.

Forming: The kneaded carbon paste is extruded into a green body (or green product) with a certain shape, size, density and strength in a molding equipment. The paste has a plastic deformation under the external force.

Roasting also called baking, It is a high temperature treatment, making the coal pitch carbonized to coke formed, which consolidate the carbonaceous aggregates and powder particles together with high mechanical strength, lower resistivity, better thermal stability and chemical stability.

Secondary roasting is to bake one more time, making the penetrating pitch carbonized . Electrodes (all types except RP) and nipples that require higher bulk density are required to be second-baked, and nipples three-dip four-bake or two-dip three-bake.

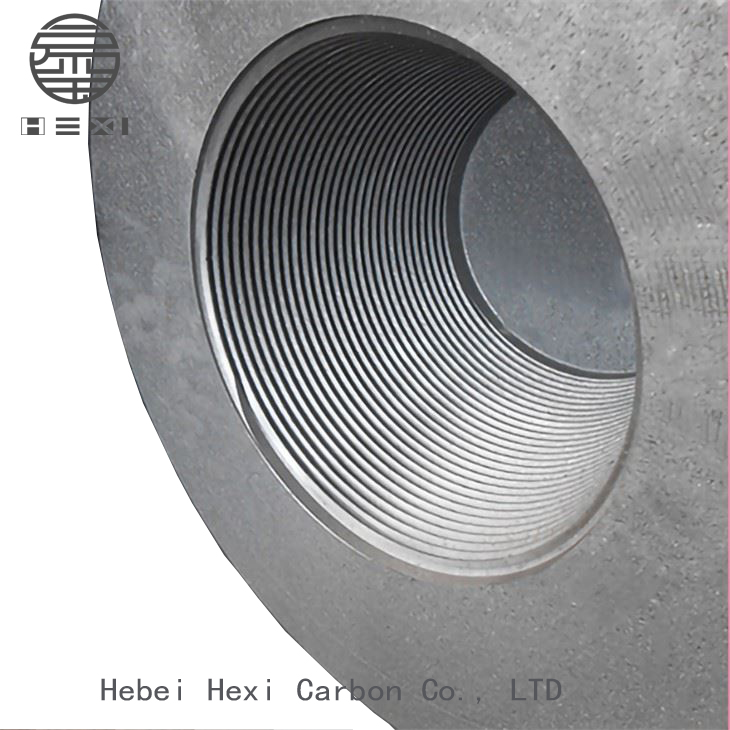

Product detail pictures:

Related Product Guide:

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for Factory wholesale High Power Graphite Electrode - 400 UHP graphite electrode – Hexi, The product will supply to all over the world, such as: US, South Korea, Riyadh, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.