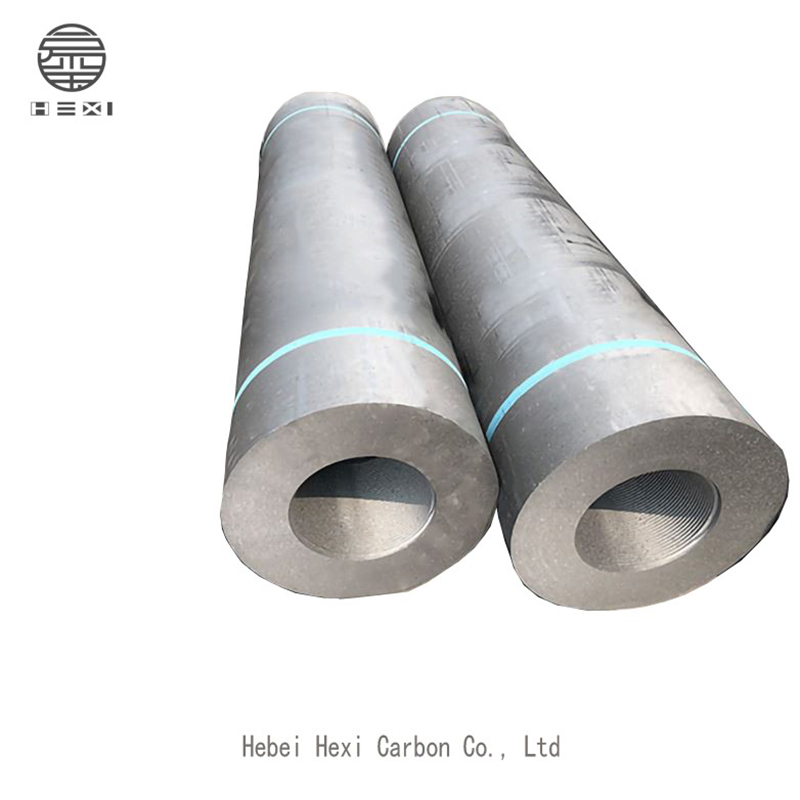

Factory source Electric Arc Furnace Graphite Electrode - UHP 550mm Graphite Electrode – Hexi

Factory source Electric Arc Furnace Graphite Electrode - UHP 550mm Graphite Electrode – Hexi Detail:

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure.

What’s the funtion of graphitization?

*Improve the electrical and thermal conductivity

*Improve the thermal shock resistance and chemical stability (the linear expansion coefficient is reduced by 50-80%);

*Make the carbon material have lubricity and wear resistance;

*Discharge impurities and improve the purity of the carbon material (the ash content of the product is reduced from 0.5% to about 0.3%).

Product detail pictures:

Related Product Guide:

Every member from our high efficiency sales team values customers' needs and business communication for Factory source Electric Arc Furnace Graphite Electrode - UHP 550mm Graphite Electrode – Hexi, The product will supply to all over the world, such as: Johannesburg, Amman, Los Angeles, With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!