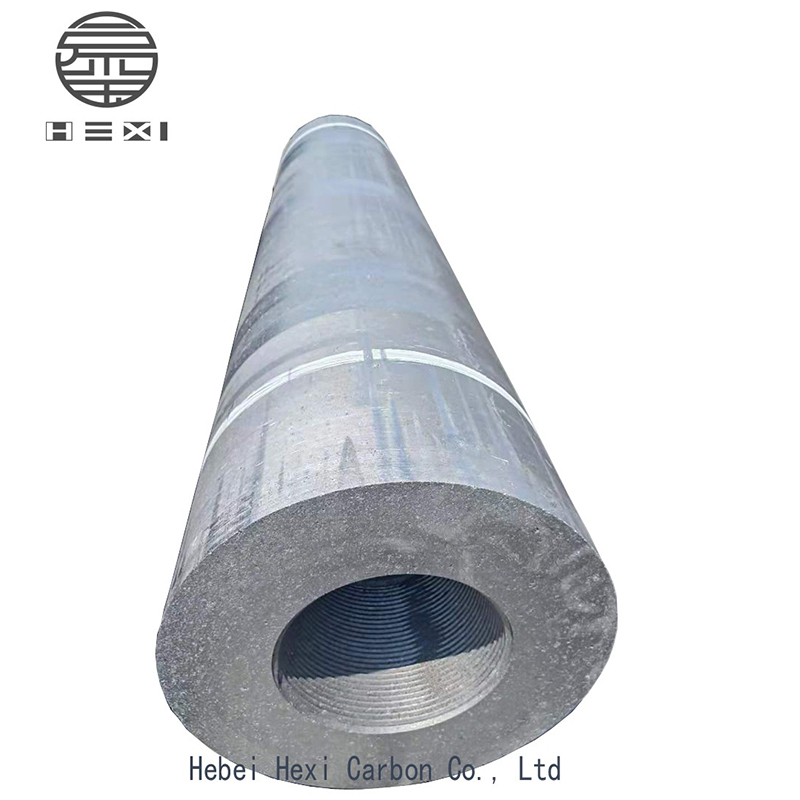

Factory Promotional Graphite Electrode Uhp 500 - 450mm high power graphite electrod – Hexi

Factory Promotional Graphite Electrode Uhp 500 - 450mm high power graphite electrod – Hexi Detail:

HP graphite electrode is mainly made of petroleum coke and needle coke, It is capable of carrying the current density 18-25A/cm2. It is designed for high power electric arc furnace steel-making.

| Comparison Technical Specification for HP Graphite Electrode 18″ | ||

| Electrode | ||

| Item | Unit | Supplier Spec |

| Typical Characteristics of Pole | ||

| Nominal Diameter | mm | 450 |

| Max Diameter | mm | 460 |

| Min Diameter | mm | 454 |

| Nominal Length | mm | 1800-2400 |

| Max Length | mm | 1900-2500 |

| Min Length | mm | 1700-2300 |

| Bulk Density | g/cm3 | 1.68-1.73 |

| transverse strength | MPa | ≥11.0 |

| Young’ Modulus | GPa | ≤12.0 |

| Specific Resistance | µΩm | 5.2-6.5 |

| Maximum current density | KA/cm2 | 15-24 |

| Current Carrying Capacity | A | 25000-40000 |

| (C.T.E) | 10-6℃ | ≤2.0 |

| ash content | % | ≤0.2 |

| Typical Characteristics of Nipple (4TPI/3TPI) | ||

| Bulk Density | g/cm3 | 1.78-1.83 |

| transverse strength | MPa | ≥22.0 |

| Young’ Modulus | GPa | ≤15.0 |

| Specific Resistance | µΩm | 3.5-4.5 |

| (C.T.E) | 10-6℃ | ≤1.8 |

| ash content | % | ≤0.2 |

Method of reducing electrode consumption

In recent years, with the vigorous development of China’s electric furnace steel industry, as well as the requirements for energy saving and consumption reduction experts and scholars at home and abroad conclude some effective approaches as follows:

1.Anti-oxidation mechanism of water spray graphite electrode

Through experimental research, spraying anti-oxidation solution on the surface of electrodes has proven much better in stop from side oxidation of the graphite electrode, and the anti-oxidation capacity is increased by 6-7 times. After using this method, the consumption of electrode has dropped to 1.9-2.2kg smelting a ton of steel.

2.Hollow electrode

In recent years, Western Europe and Sweden have begun to use hollow electrodes in the production of ferroalloy ore furnaces. Hollow electrodes, cylinder shape, are generally empty inside sealed with inert gas. Due to the hollowness, the baking conditions get improved and make the electrode strength higher. Generally speaking, it can save electrodes by 30%-40%, up to 50% at most.

3.DC arc furnace

DC electric arc furnace is a new type of smelting electric arc furnace newly developed in the world in recent years. From the published data abroad, DC arc furnace is one of the most effective techniques to reduce electrode consumption. Generally, electrode consumption can be reduced by about 40% to 60%. According to reports, the graphite electrode consumption of large-scale DC ultra-high power electric furnace has been reduced to 1.6kg/t.

4.Electrode surface coating technology

Electrode coating technology is a simple and effective technology to reduce electrode consumption, generally can reduce electrode consumption by about 20%. Commonly used electrode coating materials are aluminum and various ceramic materials, which have strong oxidation resistance at high temperatures and can effectively reduce the oxidation consumption of the electrode side surface. The method of electrode coating is mainly by spraying and grinding, and its process is simple and easy to use. It is the most commonly used method for protecting electrodes.

5.Impregnated electrode

Dip electrodes in chemical solution to cause chemical interaction between the electrode surface and the agents to improve the electrode’s resistance to high-temperature oxidation. This kind of electrodes can reduce electrode consumption by about 10% to 15%.

Product detail pictures:

Related Product Guide:

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for Factory Promotional Graphite Electrode Uhp 500 - 450mm high power graphite electrod – Hexi, The product will supply to all over the world, such as: Morocco, Lesotho, Angola, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.