Factory Outlets Graphite Blocks - Graphite Rod & Carbon Rod – Hexi

Factory Outlets Graphite Blocks - Graphite Rod & Carbon Rod – Hexi Detail:

Graphite rods produced by Hexi Carbon Company have good electrical conductivity, thermal conductivity, lubricity and chemical stability. Graphite rods are easy to process and cheap, and can be used in various applications: machinery, metallurgy, chemical industry, casting, nonferrous alloys, ceramics, semiconductors, medicine, environmental protection and so on. Most graphite rods produced by our company are used by customers for electric heating components in high temperature vacuum furnaces. High temperature resistance, the highest working temperature can reach 3000℃, excellent heat resistance and cold resistance, small thermal expansion coefficient, large thermal conductivity coefficient and resistivity (8-13) × 10-6 Ω m.

The graphite rods we produce have the following characteristics:

1. High temperature resistance: melting point 3850℃ 50℃

2. Thermal shock resistance: It has good thermal shock resistance and small thermal expansion coefficient, so it has good stability.

3. Excellent thermal and electrical conductivity. Its thermal conductivity is 4 times higher than that of stainless steel, 2 times higher than that of carbon steel and 100 times higher than that of ordinary nonmetal.

4. Lubricity: The lubricity of graphite rod is similar to that of molybdenum disulfide, the friction coefficient is less than 0.1, and its lubricity varies with the scale size. The larger the ratio, the smaller the friction coefficient and the better the lubricity.

5. Chemical stability: Graphite has good chemical stability at room temperature and is resistant to acid, alkali and organic solvents

Hexi carbon has a strong production capacity of graphite rod/carbon rod. According to different customers’ applications, we provide customized cutting sizes, which can manufacture graphite rods | carbon rods that meet your requirements, with diameters ranging from 50 mm to 1200 mm.

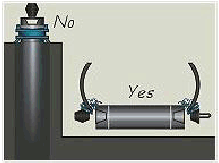

Connection of electrodes

For the connection of the electrode, the thread of the electrode should be cleaned first, and the joint should be carefully screwed into one end of the electrode, and the lifting joint should be screwed into the other end of the electrode. It is not recommended to install the joint directly into the electrode being used on the furnace.

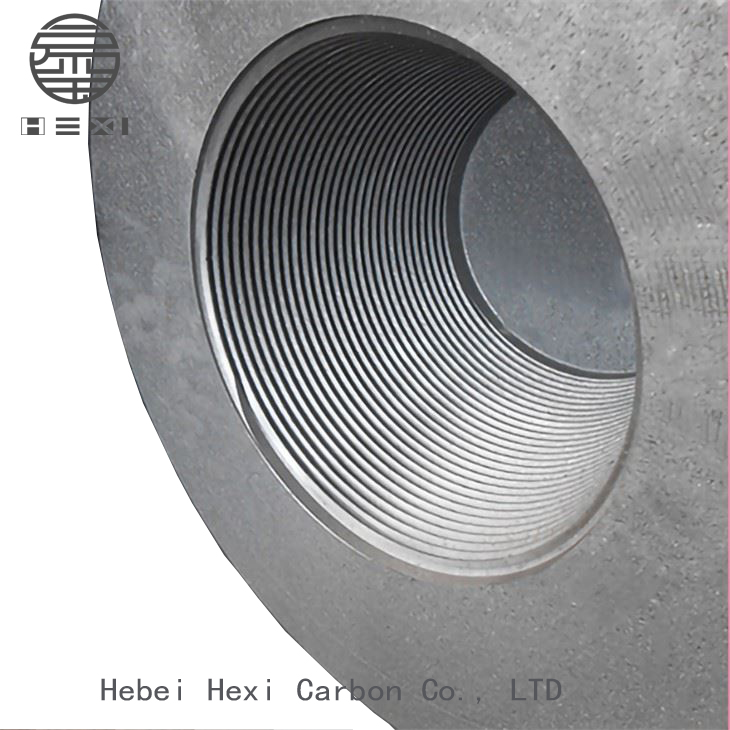

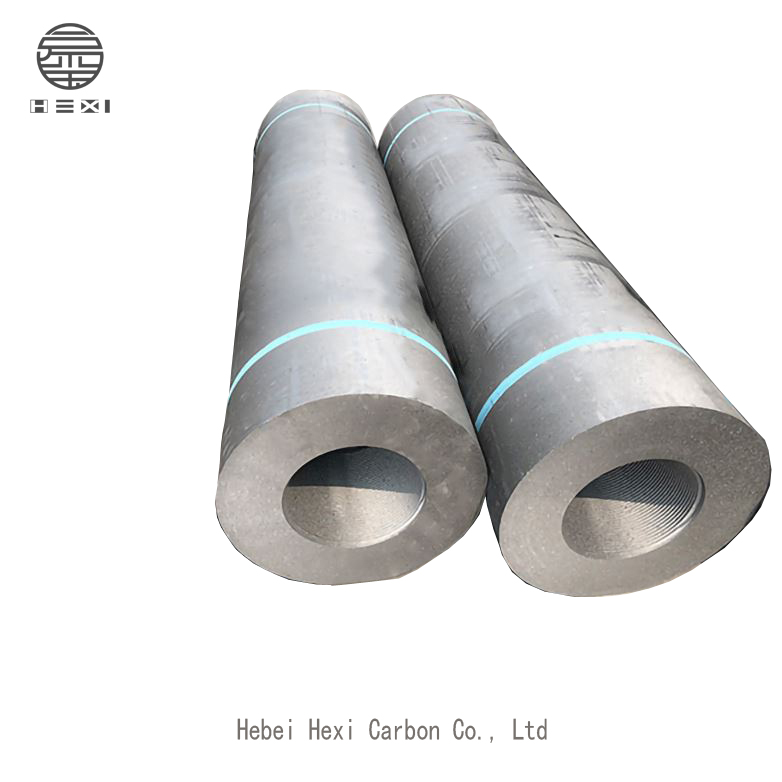

Product detail pictures:

Related Product Guide:

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for Factory Outlets Graphite Blocks - Graphite Rod & Carbon Rod – Hexi, The product will supply to all over the world, such as: Madras, Czech Republic, Poland, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!