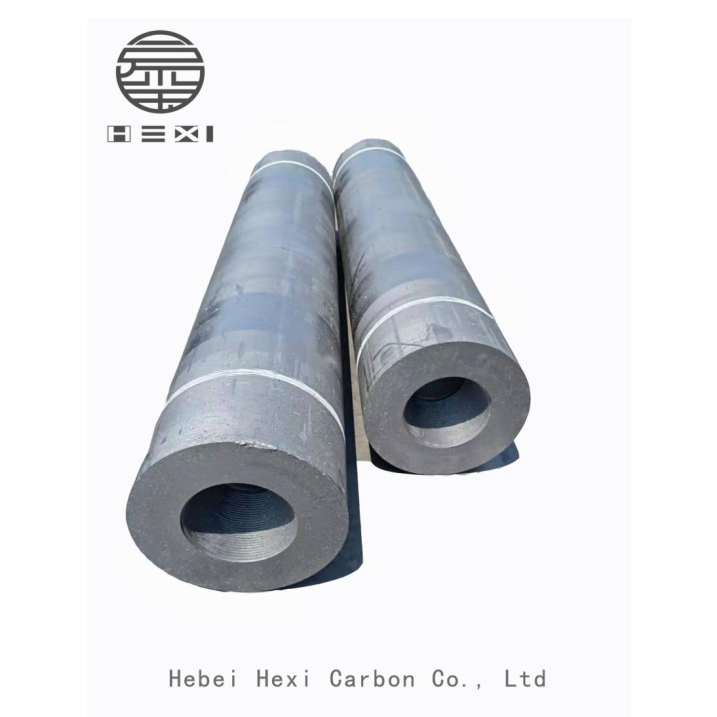

Factory Free sample High Carbon Graphite Electrode - 500mm high power graphite electrode – Hexi

Factory Free sample High Carbon Graphite Electrode - 500mm high power graphite electrode – Hexi Detail:

HP and UHP series of graphite electrode are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace.

HP 500mm graphite electrodes are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace.

The loss of graphite electrodes in electric furnace steelmaking is very common, what are they and what is it related to? The following description is for your reference.

Physical loss

The physical loss of the electrode mainly refers to the end consumption and side consumption of the electrode, which is mainly caused by mechanical external force and electromagnetic force. It is concluded as follows

Looseness and breakage at the joint, cracking of the electrode and part of the thread of the joint falling off, which is caused by poor quality of the electrode itself,

In terms of equipment, improper electrode diameter selection, poor electrode holder, lifting and control devices;In terms of operation, large pieces of scrap collapses, hitting the electrode and poor connection between two electrodes

Chemical loss

Mainly refers to the consumption of the electrode surface, including the consumption of the electrode end and side. Generally speaking, the end consumption can reach 50% of the total electrode consumption, and the side consumption is about 40%. The larger the contact area between the electrode and the air, the greater the intensity of the oxidation reaction, and the consumption will increase accordingly.

Physical Dimension

|

Nominal Diameter |

Actual Diameter |

Nominal length and deviation |

||||||||

|

Max |

Min |

1800 |

2100 |

2400 |

2700 |

|||||

|

Standard |

Short |

Standard |

Short |

Standard |

Short |

Standard |

Short |

|||

|

500 |

511 |

505 |

±100 |

-275 |

±125 |

-275 |

±125 |

-275 |

+200/ -150 |

-300 |

Typical Properties

|

Properties |

Position |

Unit |

HP |

|

Specific Resistance |

Body |

μΩm |

5.8-6.6 |

|

Nipple |

4.2-5.0 |

||

|

Bending Strengh |

Body |

Mpa |

10.0-13.0 |

|

Nipple |

18.0-22.0 |

||

|

Young’s Modulus |

Body |

Gpa |

8.0-12.0 |

|

Nipple |

14.0-16.0 |

||

|

Bulk Density |

Body |

g/cm3 |

1.62-1.66 |

|

Nipple |

1.74-1.80 |

||

|

CTE(100-600°C) |

Body |

×10 -6/゚C |

1.6-1.9 |

|

Nipple |

1.1-1.4 |

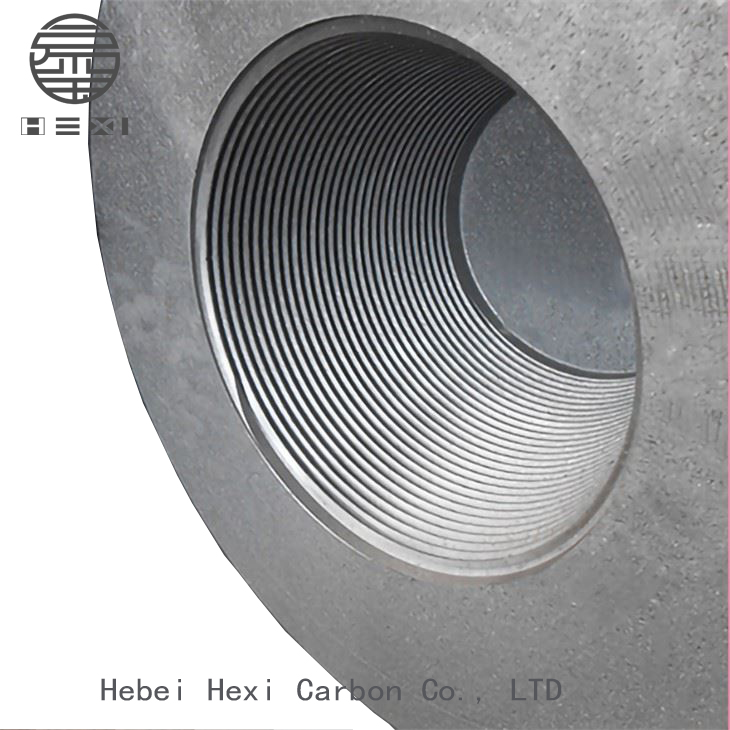

Product detail pictures:

Related Product Guide:

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for Factory Free sample High Carbon Graphite Electrode - 500mm high power graphite electrode – Hexi, The product will supply to all over the world, such as: Argentina, Malaysia, Croatia, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.