Competitive Price for Fine Graphite Powder - Graphite Block & Graphite Cube – Hexi

Competitive Price for Fine Graphite Powder - Graphite Block & Graphite Cube – Hexi Detail:

The production process of graphite block/graphite square is similar to that of graphite electrode, but it is not a by-product of graphite electrode. It is a square product of graphite electrode, which is made of graphite block material by crushing, sieving, batching, forming, cooling roasting, dipping and graphitization. There are many kinds of graphite blocks/graphite squares, and the manufacturing process is very complicated. The general production cycle is more than 2 months. According to production types, it can be divided into: extrusion, die pressing and isostatic pressing; according to particles, it can be divided into: fine particles, medium coarse particles and coarse particles. Our company can produce any specifications below 3600 mm in length, 850 mm in width and 850 mm in height, and provide graphite block | graphite square, which has the characteristics of high bulk density, low resistivity, oxidation resistance, corrosion resistance, high temperature resistance, good conductivity and light weight, and is mainly used for large DC.

Main specifications are 300*560*2100/2600/3000,350*400*1350,370*660*2400,370*870*2230,380*380*2100,420*420*1800,400*500*3600,420*640*3600,520*520*2100,610*660*2450,580*580*1950,1200*1350*370…And many other specifications.

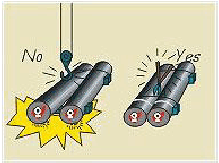

Use of electrodes

When the electrode is in use, special tools should be used to cut the ladle belt instead of crane.

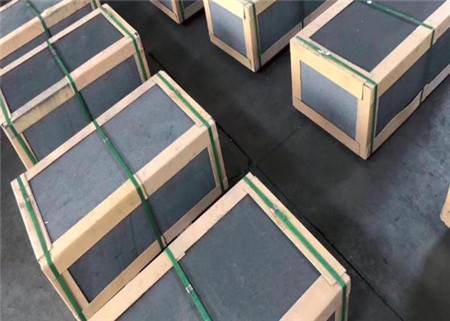

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Competitive Price for Fine Graphite Powder - Graphite Block & Graphite Cube – Hexi, The product will supply to all over the world, such as: Kuwait, Japan, Singapore, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!