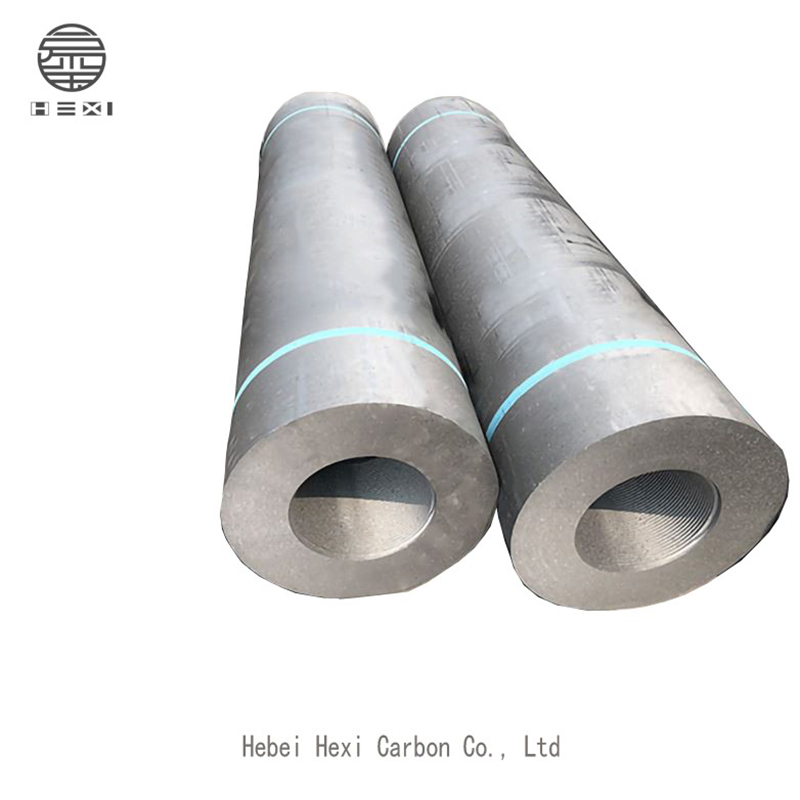

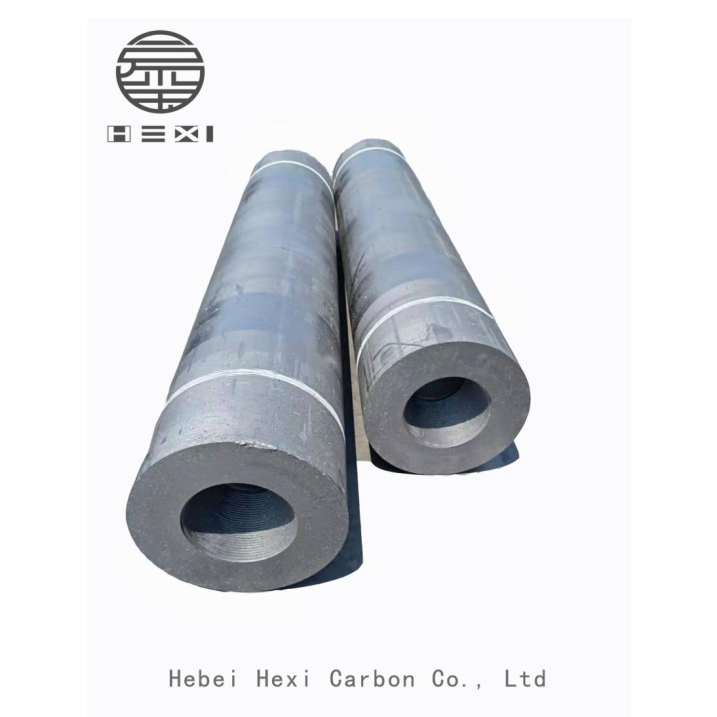

Best quality Graphite Electrode For Melting Steel - RP 350 Ordinary power graphite electrode – Hexi

Best quality Graphite Electrode For Melting Steel - RP 350 Ordinary power graphite electrode – Hexi Detail:

|

The products of Hexi have passed ISO9001 quality management system certification and obtained the export qualification of graphite electrode authorized by Chinese government. With good quality and excellent after-sales service, our products are in great demand in the world market.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Graphitization refers to the high temperature heat treatment process of transforming amorphous carbon into three-dimensional ordered planar hexagonal mesh laminated graphite by heating carbon products to 2300℃ or above in a high temperature electric furnace. The graphitization of carbon materials is carried out at a high temperature of 2300 ~ 3000℃. Because the combustion of fossil fuels is difficult to obtain such a high temperature, it can only be achieved by electric heating roasting in industry.

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Best quality Graphite Electrode For Melting Steel - RP 350 Ordinary power graphite electrode – Hexi, The product will supply to all over the world, such as: UK, Amman, Vietnam, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.