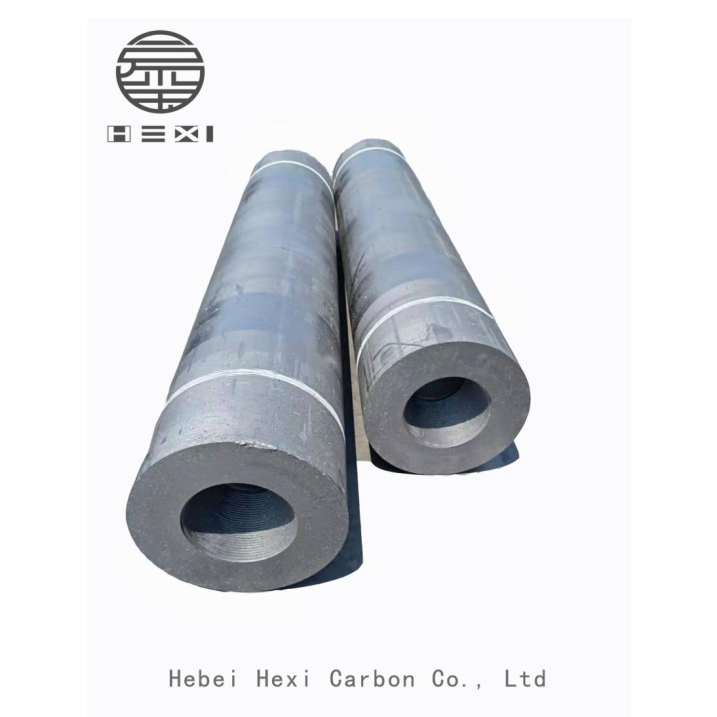

2021 wholesale price Graphite Electrodes For Furnace Melting - HP 400mm graphite electrode – Hexi

2021 wholesale price Graphite Electrodes For Furnace Melting - HP 400mm graphite electrode – Hexi Detail:

The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing.

|

High power graphite electrode and joint standard |

|||||

|

items |

unit |

nominal diameter(mm) |

|||

|

200~400 |

450~550 |

550~700 |

|||

|

specific resistance |

electrode nipple |

μ Ω•m |

5.2~6.5 3.5~4.5 |

5.2~6.5 3.5~4.5 |

5.2~6.5 3.2~4.3 |

|

transverse strength |

electrode nipple |

MPa |

≥11.0 ≥22.0 |

≥11.0 ≥22.0 |

≥10.0 ≥22.0 |

|

elastic modulus |

electrode nipple |

GPa |

≤12.0 ≤15.0 |

≤12.0 ≤15.0 |

≤12.0 ≤15.0 |

|

ash content |

electrode nipple |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

bulk density |

electrode nipple |

g/m³ |

1.68~1.73 1.78~1.83 |

1.68~1.73 1.78~1.83 |

1.68~1.72 1.78~1.83 |

|

(C.T.E) |

electrode nipple |

10℃ |

≤2.0 ≤1.8 |

≤2.0 ≤1.8 |

≤2.0 ≤1.8 |

Hexi Carbon is a manufacturing company that produces, sells, exports and provides a wide range of high-power graphite electrodes. The high-power graphite electrodes produced by our company have models with diameters from 350mm to 700mm for you to choose, and other graphite electrode models you need can also be customized.

|

Allowable current load for high-power graphite electrodes |

|||||

|

nominal diameter |

allowable current |

nominal diameter |

allowable current |

||

|

mm |

A |

A/㎡ |

mm |

A |

A/㎡ |

|

200 |

6500~10000 |

18~25 |

450 |

25000~40000 |

15~24 |

|

250 |

8000~13000 |

17~27 |

500 |

30000~48000 |

15~24 |

|

300 |

13000~17500 |

17~24 |

550 |

34000~53000 |

14~22 |

|

350 |

17400~24000 |

17~24 |

600 |

38000~58000 |

13~21 |

|

400 |

21000~31000 |

16~24 |

700 |

45000~72000 |

12~19 |

Product detail pictures:

Related Product Guide:

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for 2021 wholesale price Graphite Electrodes For Furnace Melting - HP 400mm graphite electrode – Hexi, The product will supply to all over the world, such as: azerbaijan, Victoria, Spain, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.