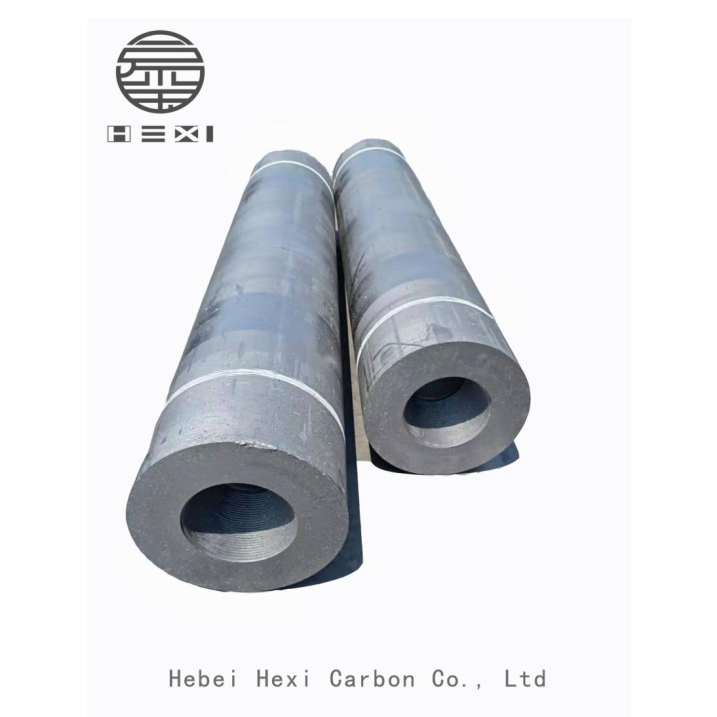

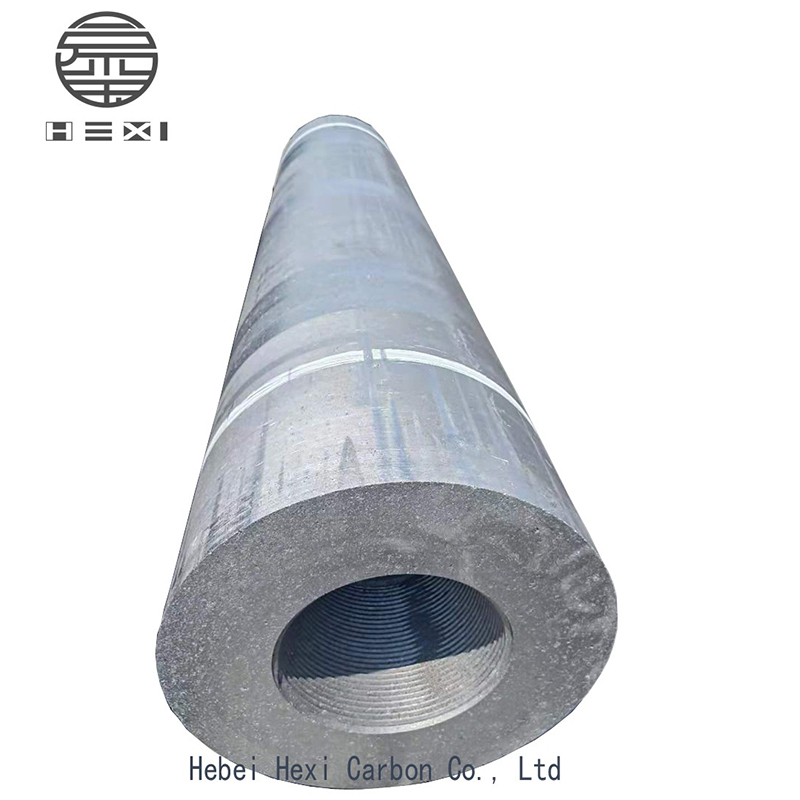

2021 Latest Design Rp Hd Hp Uhp Graphite Electrode - UHP 550mm Graphite Electrode – Hexi

2021 Latest Design Rp Hd Hp Uhp Graphite Electrode - UHP 550mm Graphite Electrode – Hexi Detail:

Graphitization is a very important stage in UHP graphite electrode production. It refers to the high-temperature heat treatment process of carbon products above 2300 ℃ in a high-temperature electric furnace to convert amorphous chaotic layer structure carbon into a three-dimensional ordered graphite crystal structure.

What’s the funtion of graphitization?

*Improve the electrical and thermal conductivity

*Improve the thermal shock resistance and chemical stability (the linear expansion coefficient is reduced by 50-80%);

*Make the carbon material have lubricity and wear resistance;

*Discharge impurities and improve the purity of the carbon material (the ash content of the product is reduced from 0.5% to about 0.3%).

| Comparison Technical Specification for UHP Graphite Electrode 22″ | ||

| Electrode | ||

| Item | Unit | Supplier Spec |

| Typical Characteristics of Pole | ||

| Nominal Diameter | mm | 550 |

| Max Diameter | mm | 562 |

| Min Diameter | mm | 556 |

| Nominal Length | mm | 1800-2400 |

| Max Length | mm | 1900-2500 |

| Min Length | mm | 1700-2300 |

| Bulk Density | g/cm3 | 1.68-1.72 |

| transverse strength | MPa | ≥12.0 |

| Young’ Modulus | GPa | ≤13.0 |

| Specific Resistance | µΩm | 4.5-5.6 |

| Maximum current density | KA/cm2 | 18-27 |

| Current Carrying Capacity | A | 45000-65000 |

| (C.T.E) | 10-6℃ | ≤1.2 |

| ash content | % | ≤0.2 |

| Typical Characteristics of Nipple (4TPI) | ||

| Bulk Density | g/cm3 | 1.78-1.84 |

| transverse strength | MPa | ≥22.0 |

| Young’ Modulus | GPa | ≤18.0 |

| Specific Resistance | µΩm | 3.4~3.8 |

| (C.T.E) | 10-6℃ | ≤1.0 |

| ash content | % | ≤0.2 |

Product detail pictures:

Related Product Guide:

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for 2021 Latest Design Rp Hd Hp Uhp Graphite Electrode - UHP 550mm Graphite Electrode – Hexi, The product will supply to all over the world, such as: belarus, Bolivia, Saudi Arabia, Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!